Exploring the Diverse Range of PCB Mount Connectors: A Comprehensive Guide

2025-04-18

Exploring the Diverse Range of PCB Mount Connectors: A Comprehensive Guide

Table of Contents

- Introduction to PCB Mount Connectors

- What Are PCB Mount Connectors?

- Types of PCB Mount Connectors

- Applications of PCB Mount Connectors

- Key Considerations for Selecting PCB Mount Connectors

- Installation Tips for PCB Mount Connectors

- Future Trends in PCB Mount Connectors

- FAQs

- Conclusion

Introduction to PCB Mount Connectors

In the realm of electronics, **PCB mount connectors** play a pivotal role in establishing reliable connections between various components on a printed circuit board (PCB). These connectors facilitate communication and power transfer, making them indispensable in a wide array of electronic devices. As we navigate through this comprehensive guide, we will explore the different types of PCB mount connectors available, their applications, and critical considerations for selecting the ideal connector for your project.

What Are PCB Mount Connectors?

PCB mount connectors are electrical components designed to connect two or more printed circuit boards or devices. They come in various shapes, sizes, and configurations, making them versatile for different applications. These connectors are typically soldered directly onto a PCB, providing a sturdy and secure connection.

The primary function of PCB mount connectors is to facilitate **signal and power transmission** within electronic devices. They ensure that signals can travel seamlessly between components, enabling devices to function effectively.

Types of PCB Mount Connectors

Understanding the various types of PCB mount connectors is crucial for selecting the right one for your project. Below, we detail some of the most common types available today.

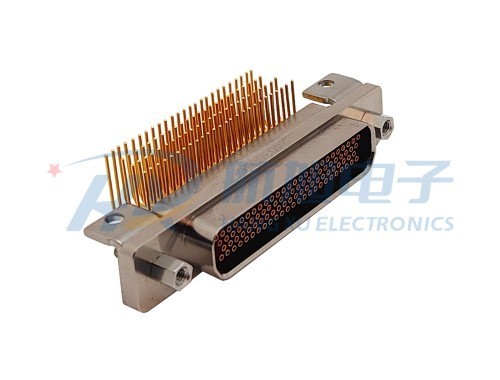

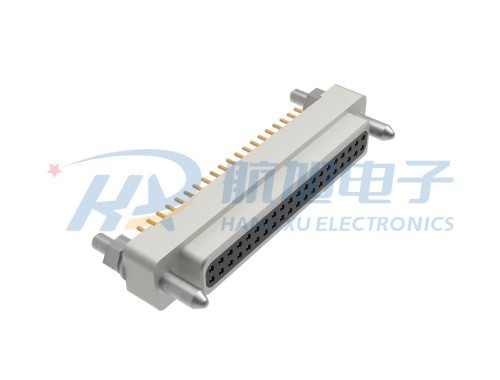

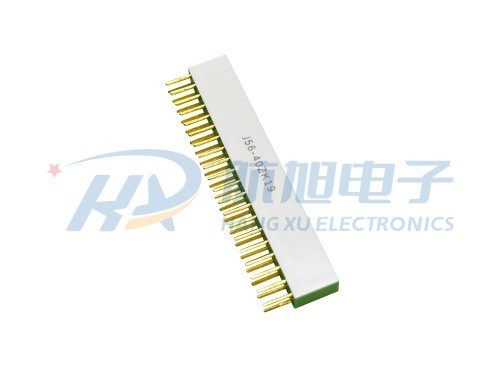

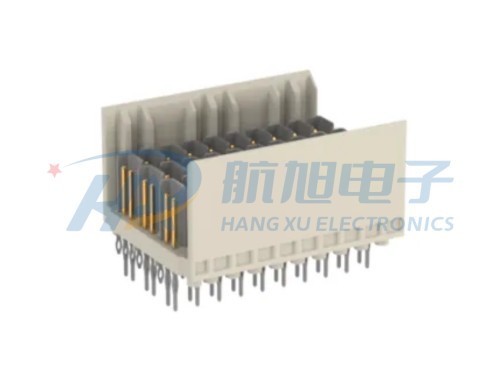

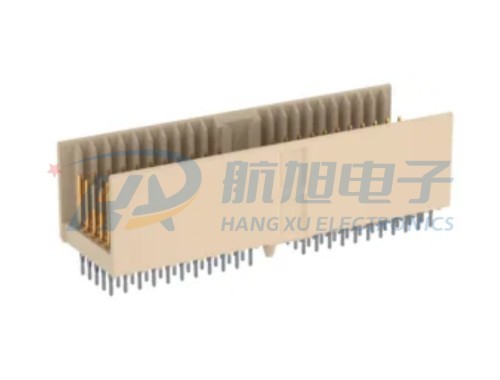

Header Pin Connectors

**Header pin connectors** are among the most commonly used types of PCB mount connectors. They consist of a row of metal pins that protrude from the PCB, allowing for easy connections with sockets or female connectors. Header pins are available in various configurations, including single-row and double-row designs, making them suitable for different applications.

One significant advantage of header pin connectors is their ability to support multiple connections in a compact space. They are widely used in both commercial and hobbyist electronic projects.

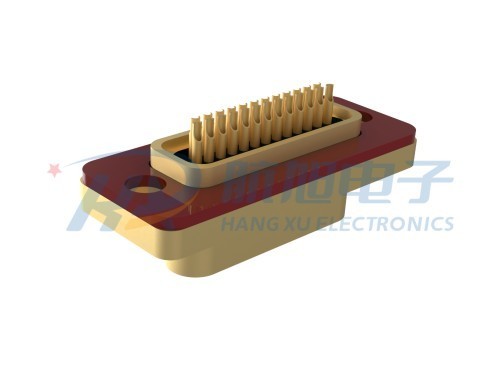

Screw Terminal Connectors

**Screw terminal connectors** provide a secure connection for wiring and are ideal for applications that require frequent disconnection and reconnection. These connectors feature a screw mechanism that clamps down on the wire, ensuring a reliable and firm connection.

Screw terminal connectors are commonly used in power supplies, industrial equipment, and home appliances. Their robustness and ease of use make them a popular choice for professionals and DIY enthusiasts alike.

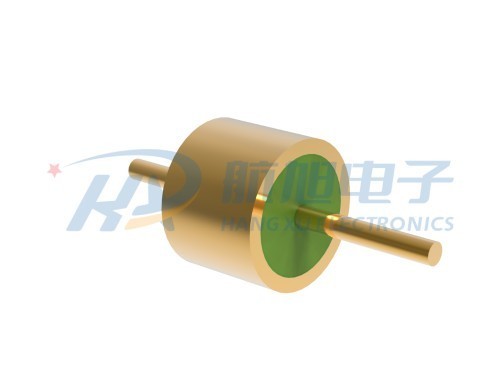

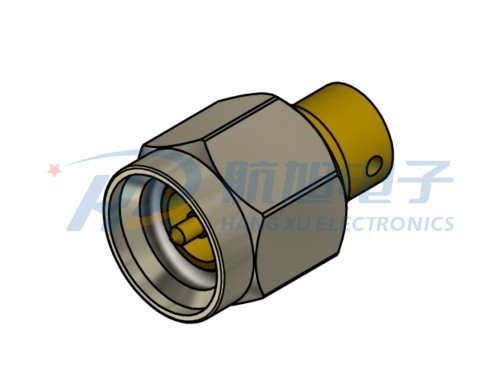

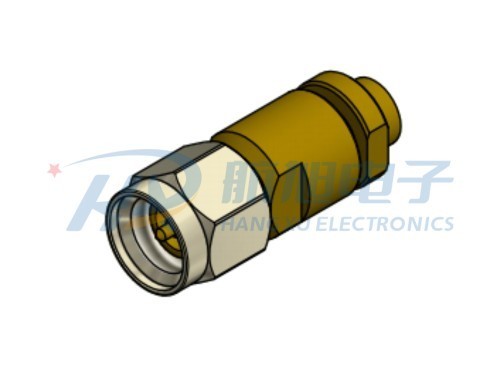

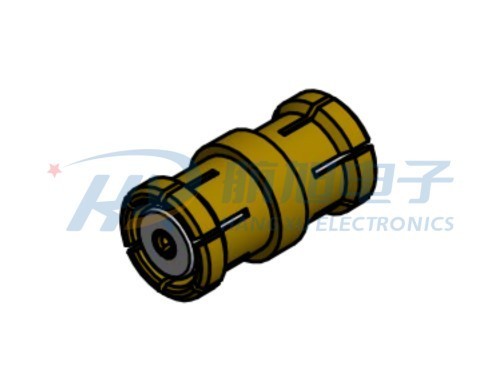

RCA Connectors

**RCA connectors**, also known as **phono connectors**, are commonly found in audio and video applications. These connectors allow for the connection of various audio devices, such as speakers and amplifiers, to a PCB. RCA connectors typically feature a cylindrical shape with a central pin for connection.

The color-coded system of RCA connectors (red, white, and yellow) aids in easy identification, making them user-friendly. Their widespread use in consumer electronics makes them a staple in many designs.

USB Connectors

**USB connectors** are essential for enabling data transfer and power supply between devices. With different formats such as USB-A, USB-B, and USB-C, these connectors are versatile and compatible with a wide range of devices.

USB connectors are widely used in computers, smartphones, and peripherals, making them a crucial component in modern electronics. Their ability to provide both data and power in a single connection has made them incredibly popular.

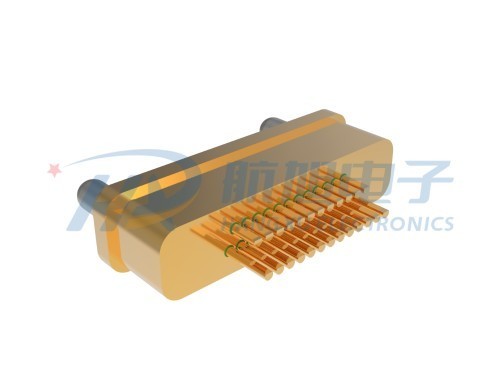

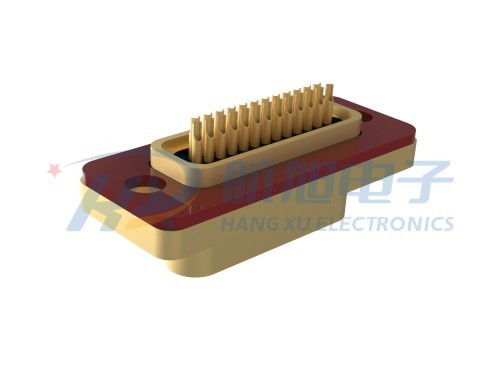

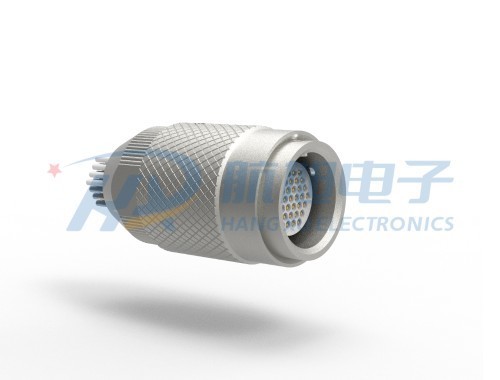

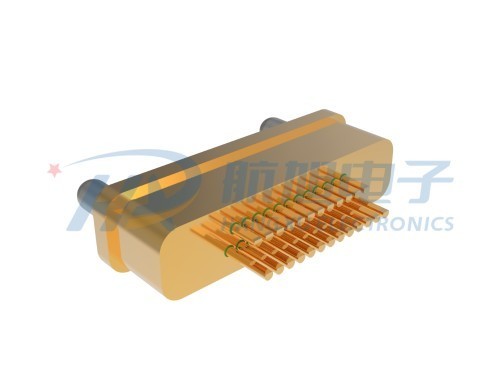

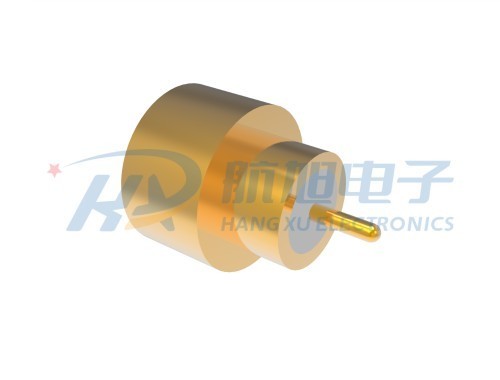

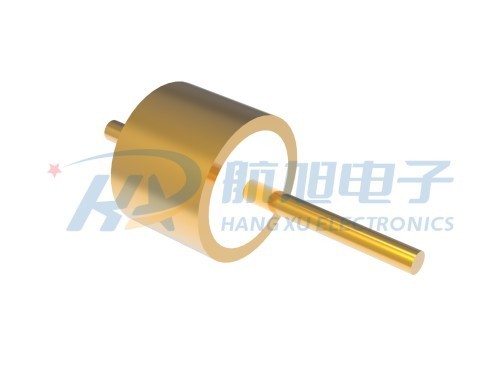

Miniature Connectors

**Miniature connectors** are designed for applications where space is at a premium. These compact connectors maintain high performance despite their small size. They are often used in portable devices, medical equipment, and telecommunications.

The compact design of miniature connectors allows for a dense arrangement of components on a PCB, making them ideal for miniaturized electronic devices.

Applications of PCB Mount Connectors

PCB mount connectors find applications across a vast array of industries. Some of the key sectors where these connectors are utilized include:

- **Consumer Electronics**: From smartphones to televisions, PCB mount connectors are integral for seamless operation.

- **Automotive**: In modern vehicles, connectors facilitate communication between sensors, control units, and displays.

- **Industrial Automation**: These connectors support equipment used in manufacturing, ensuring reliable connections in demanding environments.

- **Telecommunications**: PCB mount connectors are essential for networking equipment, providing robust connections for data transmission.

- **Medical Devices**: In medical technology, connectors ensure safe and reliable operation for critical devices.

The versatility of PCB mount connectors makes them suitable for virtually any electronic application, highlighting their importance in modern technology.

Key Considerations for Selecting PCB Mount Connectors

Choosing the right PCB mount connector for your application involves evaluating several factors. Here are some essential considerations to keep in mind:

- **Size and Space**: Assess the available space on your PCB and choose connectors that fit within the design constraints.

- **Current and Voltage Ratings**: Ensure that the selected connector can handle the required current and voltage levels for your application.

- **Environmental Factors**: Consider factors such as temperature, humidity, and exposure to chemicals that may affect the connector's performance.

- **Material Compatibility**: Check that the connector materials are compatible with the PCB and other components to prevent corrosion and degradation.

- **Ease of Installation**: Look for connectors that are easy to install and maintain, especially if frequent disconnections are anticipated.

By taking these factors into account, you can ensure that you select the most suitable PCB mount connector for your specific needs.

Installation Tips for PCB Mount Connectors

Proper installation is crucial to the functionality and longevity of PCB mount connectors. Here are some tips to ensure a successful installation:

- **Clean the PCB**: Before installation, ensure that the PCB is free from dust, grease, and other contaminants to promote a secure connection.

- **Use the Right Tools**: Employ the appropriate tools for soldering and securing connectors to avoid damage during installation.

- **Follow Manufacturer Guidelines**: Adhere to the specifications and recommendations provided by the connector manufacturer for optimal performance.

- **Test Connections**: After installation, conduct tests to verify that all connections are functioning correctly and that there are no shorts or loose connections.

Following these tips will help you achieve a reliable connection, enhancing the overall performance of your electronic device.

Future Trends in PCB Mount Connectors

The landscape of PCB mount connectors is evolving rapidly due to advancements in technology. Here are some trends to watch for in the coming years:

- **Increased Miniaturization**: As devices continue to shrink, the demand for smaller, more compact connectors will grow.

- **Enhanced Performance**: Innovations in materials and designs will lead to connectors that offer better performance in challenging environments.

- **Smart Connectors**: The integration of smart technology into connectors will allow for improved diagnostics and monitoring capabilities.

- **Sustainability**: With a growing emphasis on eco-friendly practices, manufacturers are exploring sustainable materials and production processes for connectors.

Staying informed about these trends will enable engineers and designers to select connectors that not only meet current needs but also anticipate future demands.

FAQs

1. What is the primary function of PCB mount connectors?

PCB mount connectors facilitate electrical connections between various components on a printed circuit board, enabling signal and power transmission.

2. How do I choose the right PCB mount connector for my project?

Consider factors such as size, current and voltage ratings, environmental conditions, and ease of installation when selecting a PCB mount connector.

3. What are the most common types of PCB mount connectors?

Common types include header pin connectors, screw terminal connectors, RCA connectors, USB connectors, and miniature connectors.

4. Can PCB mount connectors be reused?

Many PCB mount connectors can be reused if they are not damaged during installation or disconnection, making them cost-effective options for prototyping.

5. What trends are shaping the future of PCB mount connectors?

Key trends include increased miniaturization, enhanced performance, the introduction of smart technology, and a focus on sustainability in manufacturing processes.

Conclusion

PCB mount connectors are essential components in the world of electronics, providing reliable connections that enable devices to function seamlessly. By understanding the different types of connectors available and considering key factors for selection and installation, engineers and designers can optimize their projects for performance and reliability. As technology continues to advance, staying informed about trends in PCB mount connectors will ensure that you are well-equipped to meet the demands of future electronic designs.

Related Documents

Related News