-

-

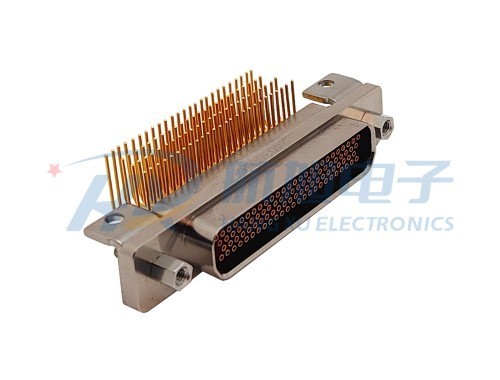

Nano-D ConnectorsMicro-D ConnectorsNano Circular ConnectorsMicro Circular ConnectorsHigh Speed ConnectorsReetangular ConnectorsPCB Mount ConnectorsAirtight ConnectorsRF ConnectorsCable AssembliesElectronic Control Module

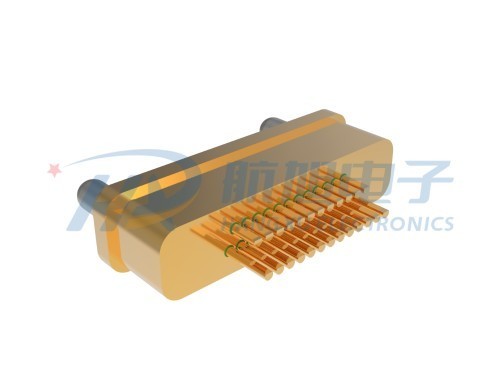

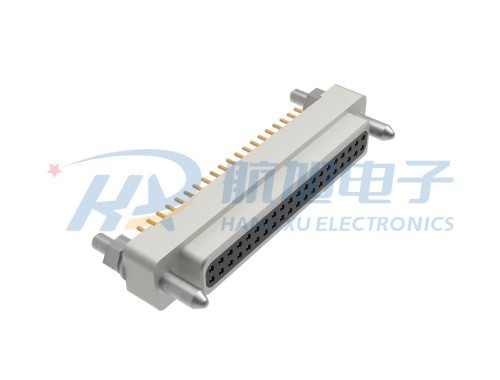

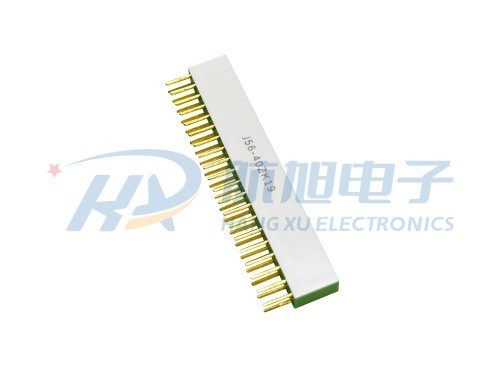

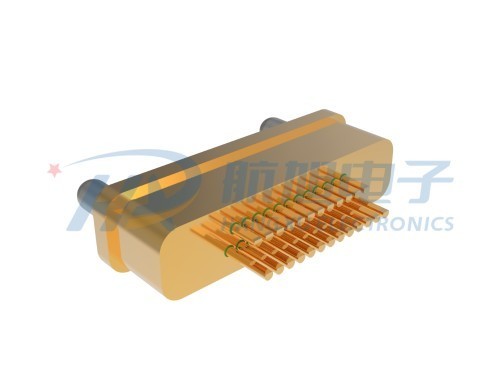

J30JZ Compact Micro-D Connectors

J30JZ Compact Micro-D Connectors J30J Micro-D Connectors

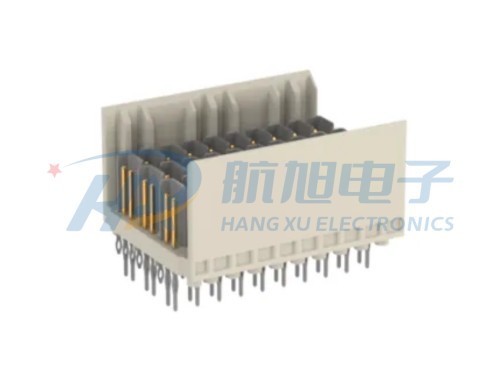

J30J Micro-D Connectors J20J Micro-D Connectors

J20J Micro-D Connectors J29A Micro-D Connectors

J29A Micro-D Connectors MDM1 Micro-D Connectors

MDM1 Micro-D Connectors MDC1 Micro-D Electrical Connector

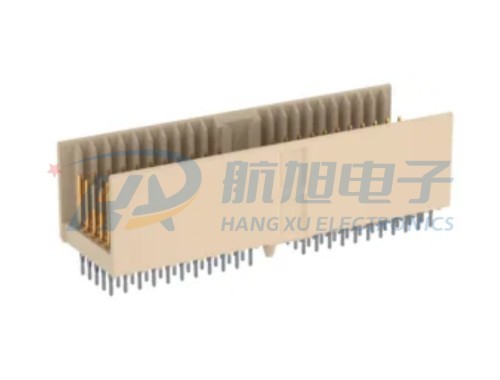

MDC1 Micro-D Electrical Connector HJ30J High-Speed Micro-D Connectors

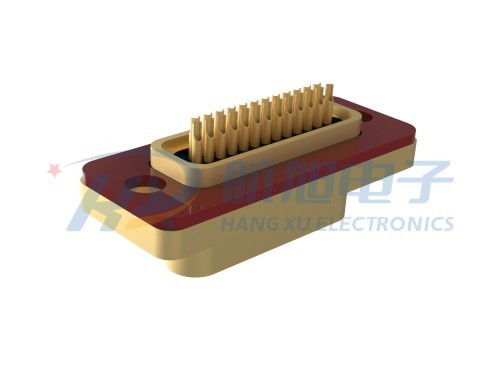

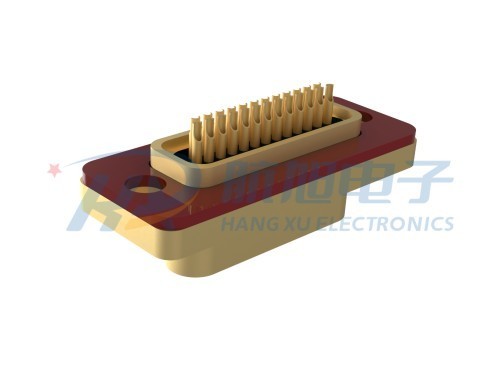

HJ30J High-Speed Micro-D Connectors J30JM Hermetic Sealed Micro-D Connectors

J30JM Hermetic Sealed Micro-D Connectors J30JM1 Gas Sealed Micro-D Connectors

J30JM1 Gas Sealed Micro-D Connectors J30JB Micro-D Connectors

J30JB Micro-D Connectors J30JMI Gas Sealed Micro-D Connectors

J30JMI Gas Sealed Micro-D Connectors J63AM Micro Electrical Connector

J63AM Micro Electrical Connector J30JM Hermetic Sealed Micro-D Connectors

J30JM Hermetic Sealed Micro-D Connectors J30JM1 Gas Sealed Micro-D Connectors

J30JM1 Gas Sealed Micro-D Connectors J30JMI Gas Sealed Micro-D Connectors

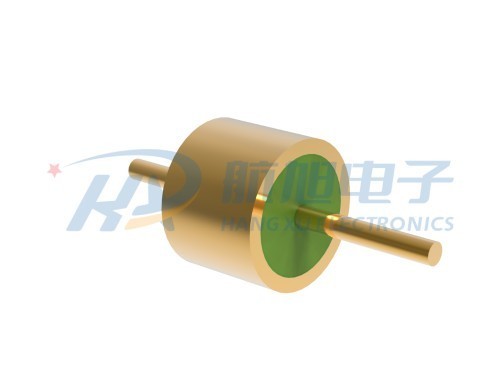

J30JMI Gas Sealed Micro-D Connectors DC Single Core Insulator

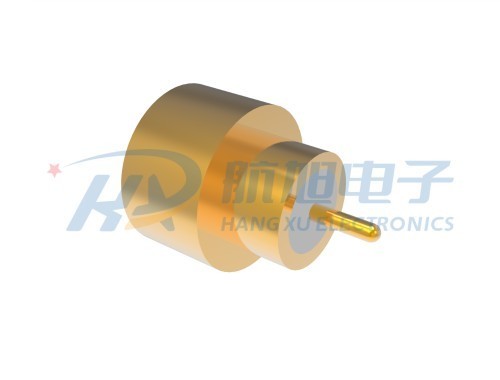

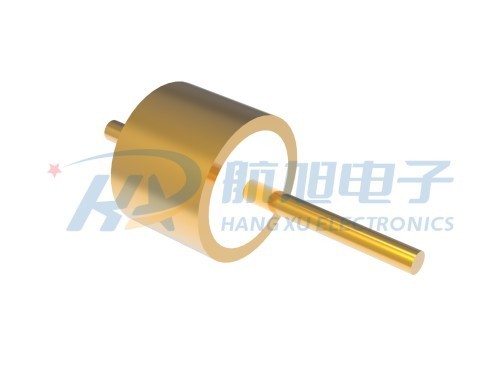

DC Single Core Insulator DC insulator series

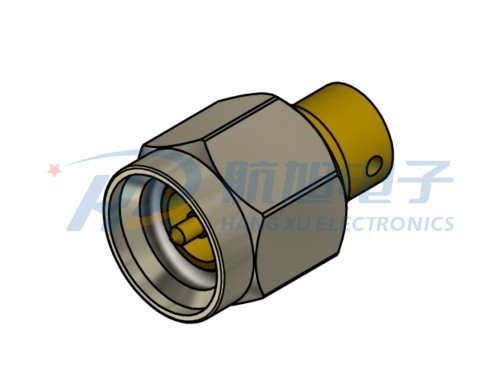

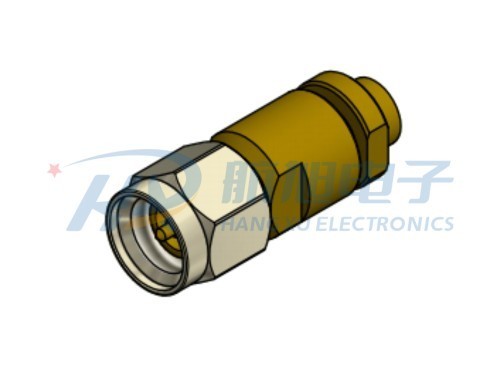

DC insulator series SMP(M)

SMP(M) RF insulator

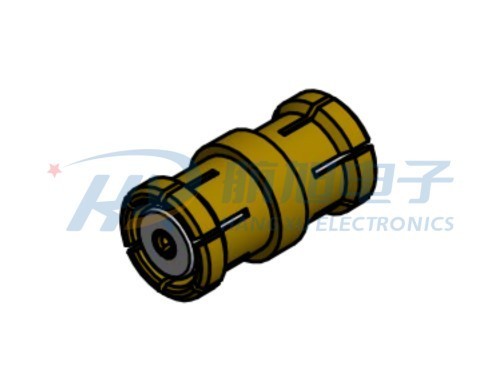

RF insulator MDCS tandem

MDCS tandem Metal sealing

Metal sealing -

-

Hangxu electronic Technology

In 2022, it was recognized as a high-tech enterprise by Guizhou Province

Understanding Airtight Connectors: Essential Insights for Electrical Professionals

2025-04-23

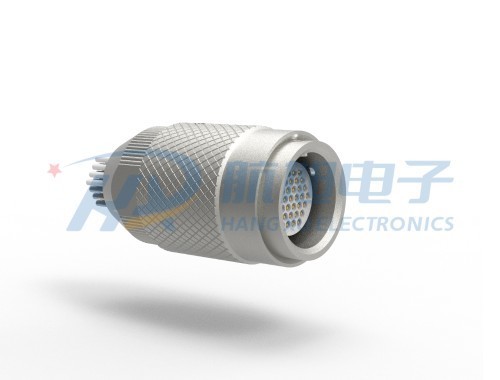

Airtight connectors are an integral component in the electrical and electronics industry, particularly in applications where moisture, dust, and environmental factors can compromise system integrity. These connectors are engineered to create a robust seal that prevents the ingress of contaminants, ensuring reliable performance and longevity in harsh conditions.

One of the primary advantages of airtight connectors is their ability to provide protection against environmental elements. In applications such as outdoor lighting, automotive systems, and industrial machinery, exposure to water and dust can lead to corrosion and failure. Airtight connectors are designed with advanced sealing technologies that maintain their integrity even in extreme conditions, significantly reducing the risk of electrical failures.

In addition to environmental protection, airtight connectors also enhance the overall durability of electrical systems. By minimizing the potential for moisture infiltration, these connectors help to prevent short circuits and other electrical malfunctions that can arise from corrosion. This is particularly crucial in critical applications such as aerospace, military, and medical devices, where reliability is paramount.

When selecting airtight connectors, several factors should be considered. The first is the specific environmental conditions of the application. Understanding the level of exposure to elements such as water, dust, and temperature fluctuations will guide the selection process. Different connectors offer varying degrees of sealing effectiveness, often rated by Ingress Protection (IP) codes. It is advisable to choose connectors with a higher IP rating for more demanding environments.

Material selection is another critical aspect. Airtight connectors are typically made from materials that not only provide a robust seal but also possess excellent electrical insulation properties. Thermoplastic elastomers and molded rubber are commonly used materials that offer flexibility and durability while maintaining an effective seal.

Moreover, the installation process of airtight connectors is essential for ensuring their functionality. Proper installation techniques should be followed to maintain the integrity of the seal. This includes using correct torquing methods and ensuring that all components are clean and free of contaminants before assembly.

In conclusion, airtight connectors are a vital component in many electrical applications, providing essential protection against environmental hazards. By understanding their features and the factors influencing their selection, electrical professionals can make informed decisions that enhance the reliability and longevity of their systems. Implementing airtight connectors effectively can lead to improved performance, reduced maintenance costs, and increased system safety.

One of the primary advantages of airtight connectors is their ability to provide protection against environmental elements. In applications such as outdoor lighting, automotive systems, and industrial machinery, exposure to water and dust can lead to corrosion and failure. Airtight connectors are designed with advanced sealing technologies that maintain their integrity even in extreme conditions, significantly reducing the risk of electrical failures.

In addition to environmental protection, airtight connectors also enhance the overall durability of electrical systems. By minimizing the potential for moisture infiltration, these connectors help to prevent short circuits and other electrical malfunctions that can arise from corrosion. This is particularly crucial in critical applications such as aerospace, military, and medical devices, where reliability is paramount.

When selecting airtight connectors, several factors should be considered. The first is the specific environmental conditions of the application. Understanding the level of exposure to elements such as water, dust, and temperature fluctuations will guide the selection process. Different connectors offer varying degrees of sealing effectiveness, often rated by Ingress Protection (IP) codes. It is advisable to choose connectors with a higher IP rating for more demanding environments.

Material selection is another critical aspect. Airtight connectors are typically made from materials that not only provide a robust seal but also possess excellent electrical insulation properties. Thermoplastic elastomers and molded rubber are commonly used materials that offer flexibility and durability while maintaining an effective seal.

Moreover, the installation process of airtight connectors is essential for ensuring their functionality. Proper installation techniques should be followed to maintain the integrity of the seal. This includes using correct torquing methods and ensuring that all components are clean and free of contaminants before assembly.

In conclusion, airtight connectors are a vital component in many electrical applications, providing essential protection against environmental hazards. By understanding their features and the factors influencing their selection, electrical professionals can make informed decisions that enhance the reliability and longevity of their systems. Implementing airtight connectors effectively can lead to improved performance, reduced maintenance costs, and increased system safety.

Related Documents

Related News

Hotline/WhatsApp:+86-13378533963

Address: No. 6, Xiaomeng Industrial Park, Economic Development Zone, Guiyang City, Guizhou, China

Official Website

WeChat Customer Service

SAF Coolest v1.3 设置面板 TUQSD-ZDBH-ZXSSE-ASE

图片ALT信息: Guizhou Hangxu Electronic Technology

违禁词: First, best, first-class, leading, unique, king, leader, leader, extreme,

无数据提示

Sorry, the current column has no content for the time being.!

You can view other columns or returnHome Page