A Deep Dive into the Benefits of Using Airtight Connectors

2025-04-28

A Deep Dive into the Benefits of Using Airtight Connectors

Table of Contents

- 1. Introduction to Airtight Connectors

- 2. What are Airtight Connectors?

- 3. Key Benefits of Using Airtight Connectors

- 3.1 Superior Sealing Properties

- 3.2 Enhanced Durability

- 3.3 Corrosion Resistance

- 3.4 Improved Performance

- 3.5 Cost-effectiveness

- 4. Applications of Airtight Connectors

- 5. Installation and Maintenance Tips

- 6. Common Misconceptions about Airtight Connectors

- 7. Frequently Asked Questions (FAQs)

- 8. Conclusion

1. Introduction to Airtight Connectors

Airtight connectors are crucial components in numerous electrical and electronic applications. They ensure the integrity and reliability of connections by preventing the ingress of moisture, dust, and other contaminants. As technology advances, the demand for robust and effective connectors continues to grow, making the understanding of airtight connectors and their benefits essential for engineers and technicians alike.

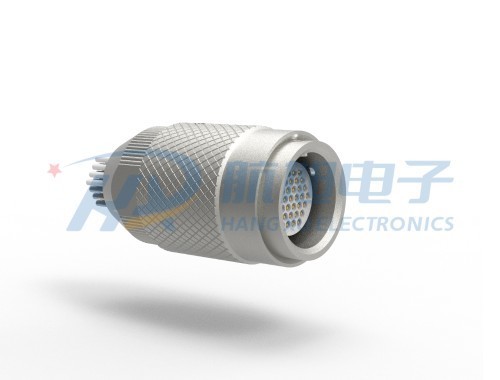

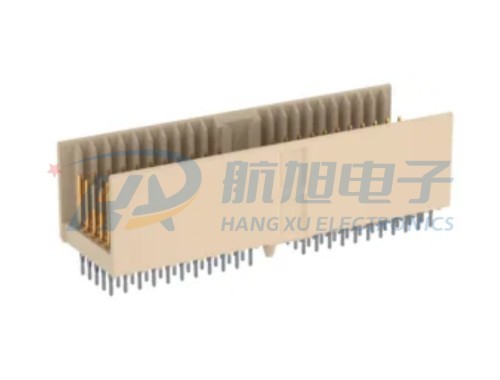

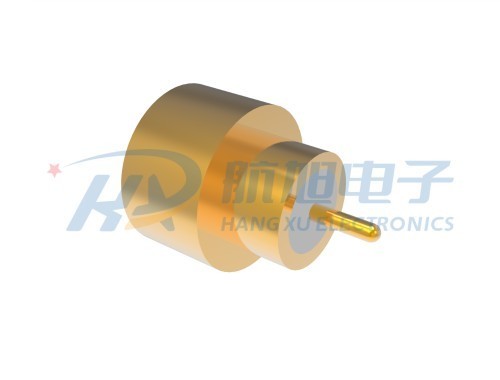

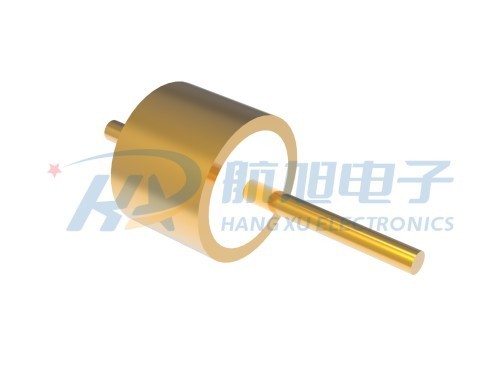

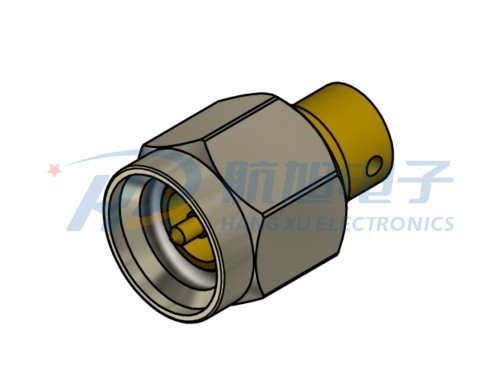

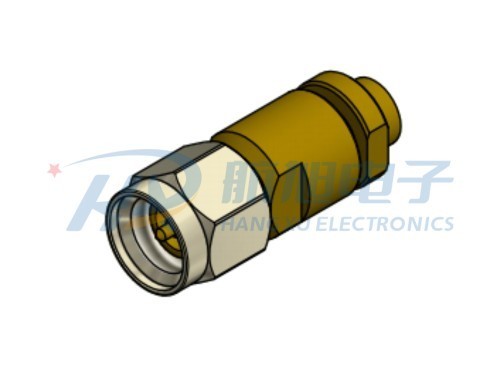

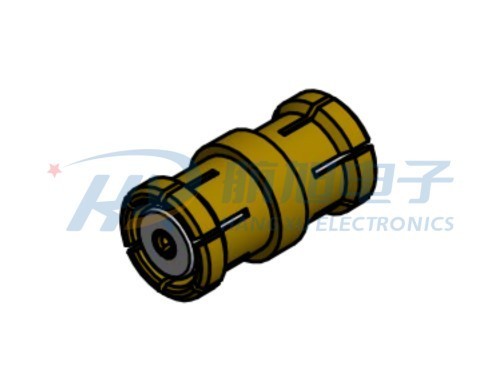

2. What are Airtight Connectors?

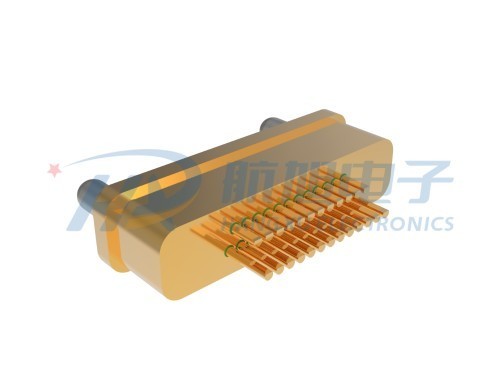

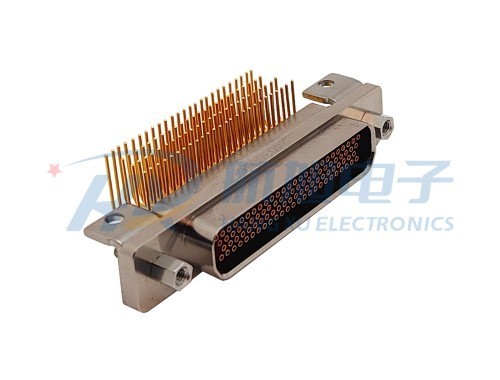

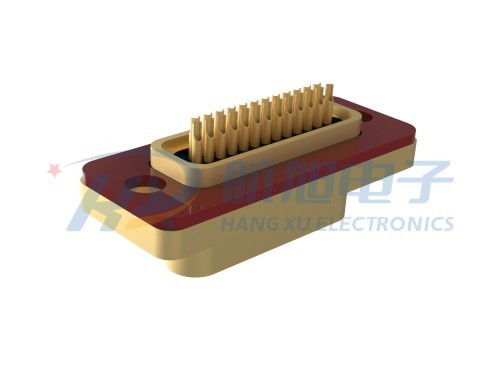

Airtight connectors are specialized connectors designed to create a sealed environment around electrical connections. These connectors utilize a combination of materials and design techniques to form a barrier against air and moisture. Commonly used in environments where exposure to harsh elements is a concern, airtight connectors are essential in maintaining the functionality and longevity of electrical systems.

3. Key Benefits of Using Airtight Connectors

When it comes to enhancing the reliability and performance of electrical connections, airtight connectors stand out. Below, we explore the key benefits in detail.

3.1 Superior Sealing Properties

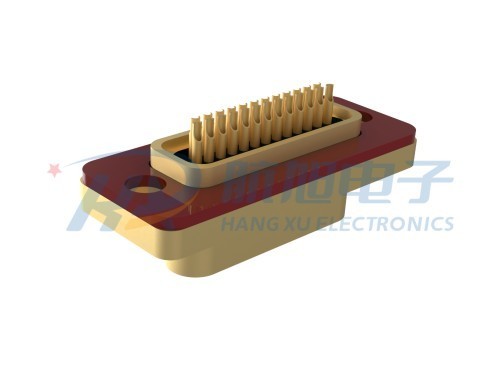

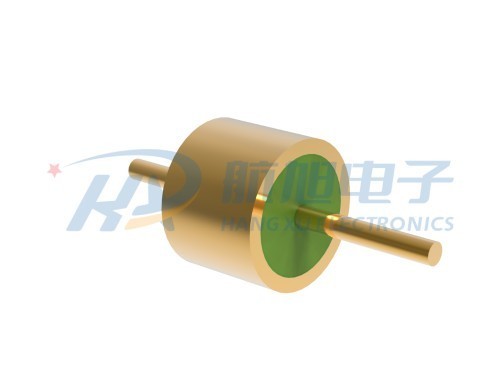

One of the most significant advantages of airtight connectors is their **superior sealing properties**. These connectors are designed with gaskets and seals that prevent moisture and dust from entering the connection points. This sealing capability is particularly important in outdoor applications or in environments where equipment is exposed to water, dust, or other contaminants.

3.2 Enhanced Durability

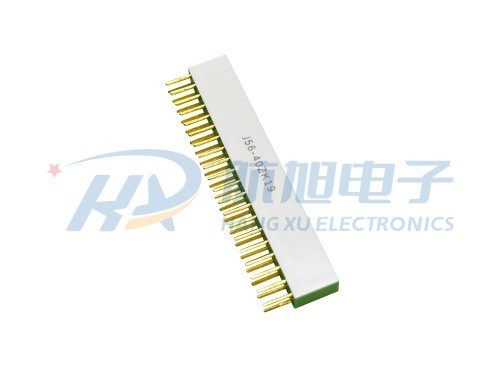

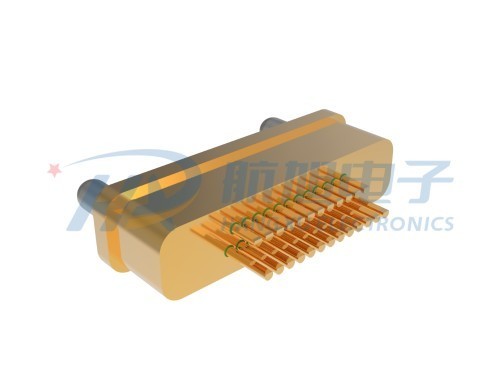

Airtight connectors are built to withstand harsh conditions, which contributes to their **enhanced durability**. Made from high-quality materials, these connectors are resistant to extreme temperatures, UV exposure, and physical impact. This resilience ensures that the connectors can maintain their integrity over time, reducing the need for frequent replacements and repairs.

3.3 Corrosion Resistance

Another critical benefit is **corrosion resistance**. Airtight connectors often feature materials that resist corrosion, making them ideal for use in marine or industrial environments where exposure to chemicals or saltwater may occur. This characteristic helps maintain the performance and safety of electrical connections, preventing failures that could be costly and dangerous.

3.4 Improved Performance

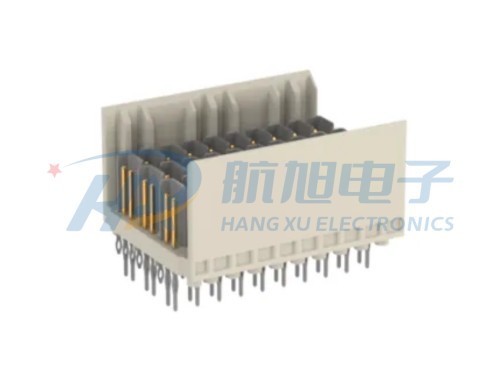

By providing a reliable barrier against the elements, airtight connectors contribute to **improved performance** of electrical systems. They help ensure consistent conductivity and reduce the risk of electrical shorts or failures. This enhanced performance can lead to greater efficiency and reliability in various applications, from automotive to aerospace.

3.5 Cost-effectiveness

While the initial investment in airtight connectors may be higher compared to standard connectors, their **cost-effectiveness** becomes evident over time. The durability and reduced maintenance requirements associated with these connectors can lead to significant savings. Fewer replacements and repairs translate to lower operational costs and improved project timelines.

4. Applications of Airtight Connectors

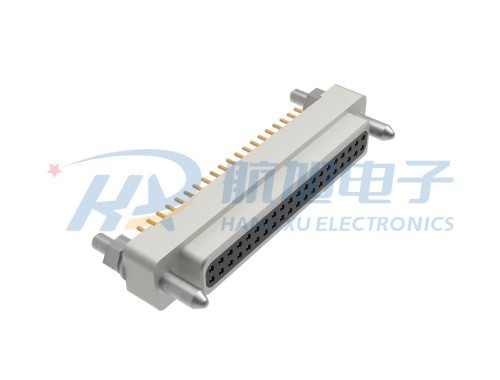

Airtight connectors are used across a wide range of industries and applications. Their versatility makes them suitable for:

- **Automotive**: In vehicles, airtight connectors are used in lighting systems, engine compartments, and other critical areas where exposure to moisture can cause electrical failures.

- **Aerospace**: The aviation industry relies on airtight connectors for critical systems to ensure safety and reliability at high altitudes where conditions can be extreme.

- **Marine**: In boats and ships, these connectors protect against saltwater corrosion and ensure that electrical systems function properly in challenging environments.

- **Industrial**: Factories and manufacturing facilities utilize airtight connectors in machinery and control systems to prevent failures caused by dust and moisture.

5. Installation and Maintenance Tips

Proper installation and maintenance are crucial for maximizing the benefits of airtight connectors. Here are some tips:

- **Choose the Right Connector**: Select connectors that are rated for your specific application. Ensure they can withstand the environmental conditions they will be exposed to.

- **Follow Installation Guidelines**: Adhere to manufacturer instructions during installation. Proper alignment and torque specifications are vital for ensuring effective sealing.

- **Regular Inspections**: Periodically inspect connectors for signs of wear or damage. Early detection of issues can prevent costly failures down the line.

6. Common Misconceptions about Airtight Connectors

Despite their advantages, several misconceptions about airtight connectors persist:

- **Misconception 1: Airtight Connectors Are Only for Outdoor Use**: While they are beneficial in outdoor applications, airtight connectors are also valuable in indoor environments where moisture or dust is a concern.

- **Misconception 2: All Connectors with Seals Are Airtight**: Not all sealed connectors offer the same level of protection. It’s essential to choose connectors specifically designed as airtight for optimal performance.

7. Frequently Asked Questions (FAQs)

1. What makes airtight connectors different from standard connectors?

Airtight connectors are designed with superior sealing mechanisms to prevent moisture, dust, and contaminants from entering the connection points, whereas standard connectors may not have this level of protection.

2. Can airtight connectors be reused?

Yes, airtight connectors can often be reused if they are inspected and found to be undamaged after disconnection.

3. Are airtight connectors more expensive than regular connectors?

Generally, airtight connectors may have a higher upfront cost, but their long-term durability and reduced maintenance needs can lead to cost savings over time.

4. How do I know if I need airtight connectors for my project?

If your application involves exposure to moisture, dust, or harsh environmental conditions, it is wise to consider using airtight connectors.

5. What materials are commonly used in airtight connectors?

Airtight connectors are often made from materials such as thermoplastic elastomers, silicone, or other durable plastics that provide resistance to environmental factors.

8. Conclusion

In summary, airtight connectors offer numerous benefits that enhance the reliability and performance of electrical connections across various applications. Their superior sealing properties, enhanced durability, and cost-effectiveness make them an essential choice for engineers and technicians. By understanding the advantages and proper usage of these connectors, professionals can significantly improve the functionality and longevity of their electrical systems. Investing in airtight connectors is a wise decision for anyone looking to ensure the success of their projects in demanding environments.

Related Documents

Related News