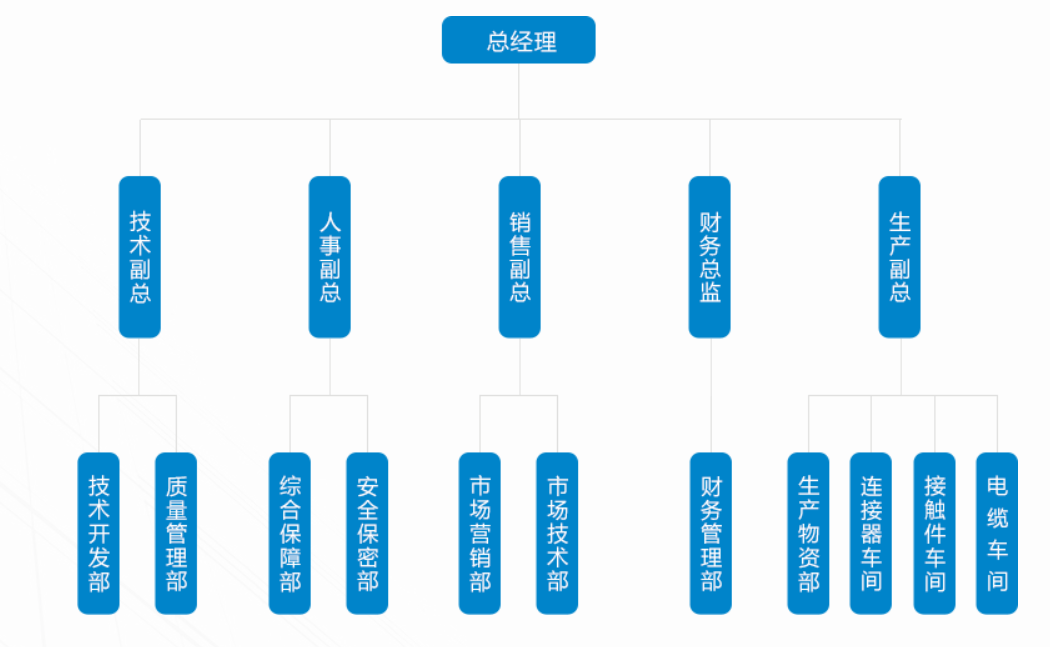

How Nano-D Airtight Connectors Enhance Performance in Harsh Environments

2025-05-18

How Nano-D Airtight Connectors Enhance Performance in Harsh Environments

Table of Contents

- 1. Introduction to Nano-D Airtight Connectors

- 2. Understanding Nano-D Technology

- 3. Key Applications of Nano-D Airtight Connectors

- 4. Benefits of Using Nano-D Airtight Connectors

- 5. Performance in Extreme Conditions

- 6. Comparison with Traditional Connectors

- 7. The Future of Nano-D Connectors in Technology

- 8. FAQs about Nano-D Airtight Connectors

- 9. Conclusion

1. Introduction to Nano-D Airtight Connectors

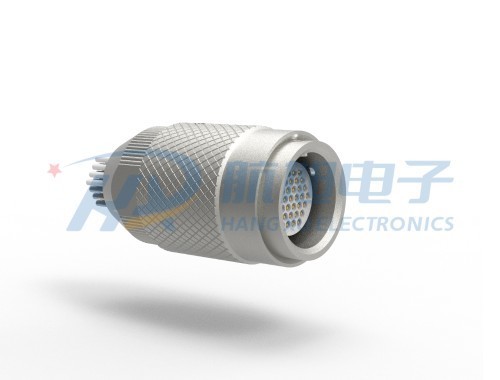

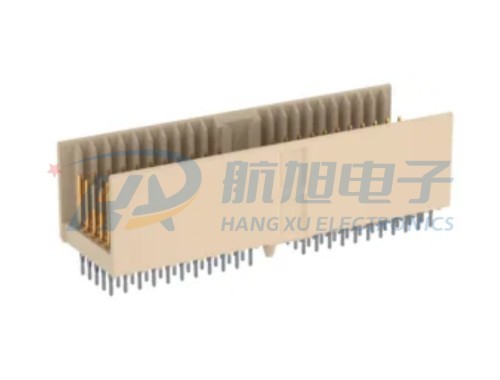

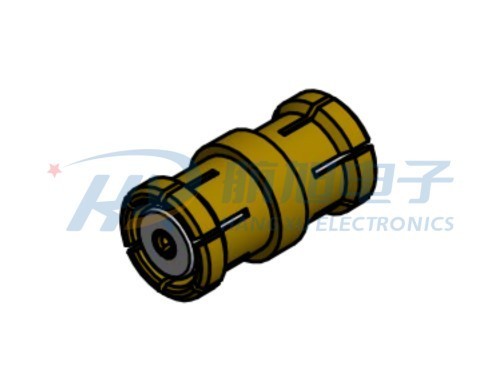

In a world where electronic devices are increasingly subjected to extreme environments, the reliability of connectors has never been more critical. **Nano-D airtight connectors** are revolutionizing the field of connectivity, particularly in sectors such as aerospace, defense, medical, and industrial applications. These connectors are engineered to withstand harsh conditions like extreme temperatures, humidity, and exposure to dust, ensuring the performance of vital electronic systems.

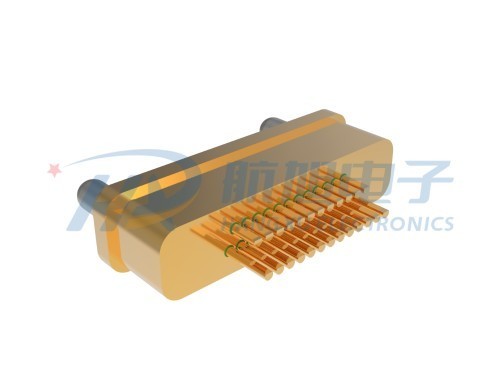

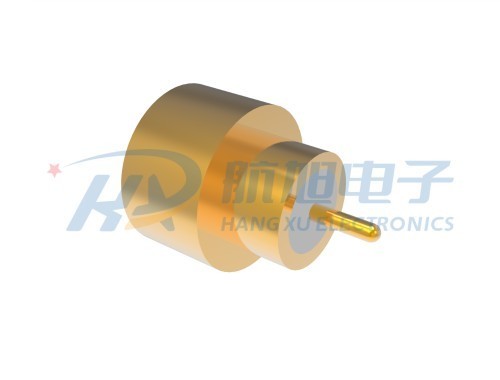

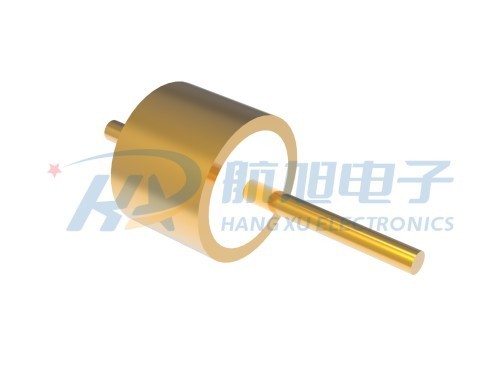

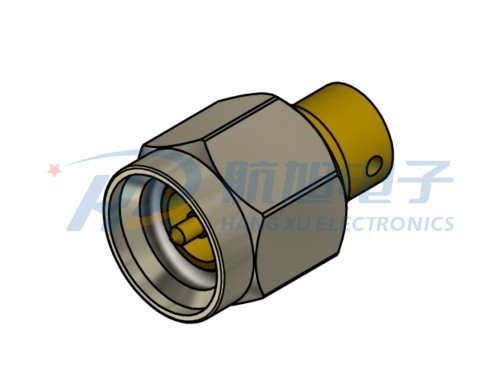

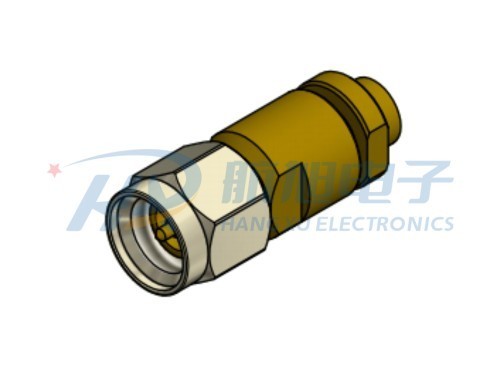

2. Understanding Nano-D Technology

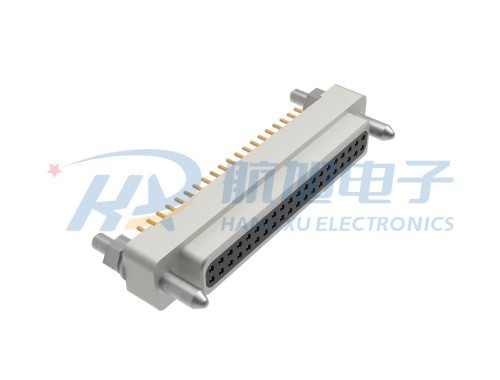

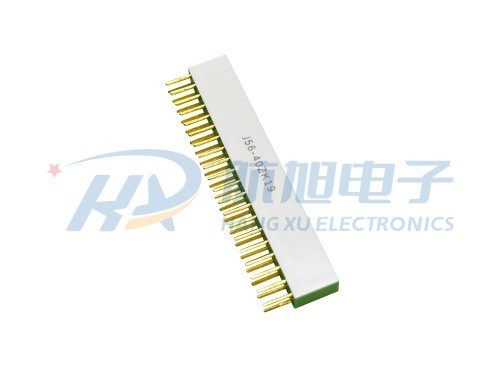

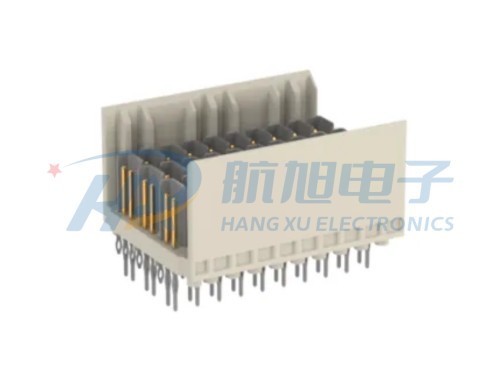

Nano-D connectors are an advanced style of miniature circular connectors featuring a compact design and high-density pin configurations. **Their waterproof and dustproof capabilities are essential for maintaining functionality in challenging environments.** The technology behind these connectors involves several key elements:

2.1 Miniaturization

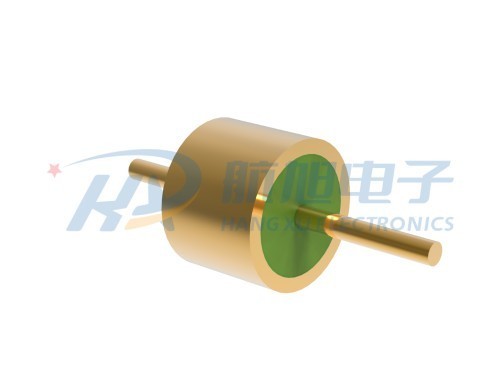

The **miniaturization** of electronic components allows for smaller, lighter devices without sacrificing performance. Nano-D connectors typically feature a small footprint, which is vital in modern technology where space is often at a premium.

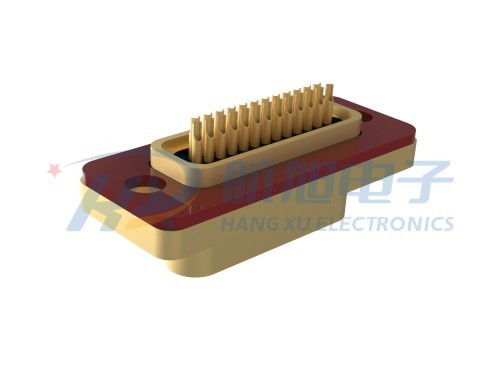

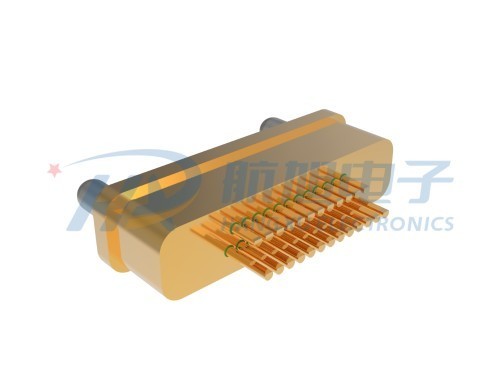

2.2 Airtight Sealing

These connectors utilize **advanced sealing methods** to ensure airtight performance. This feature is crucial for preventing moisture ingress and contamination, which can lead to system failures.

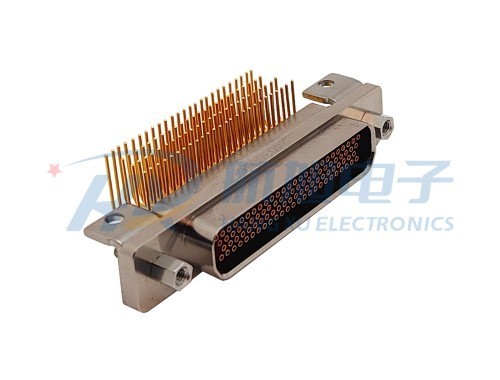

2.3 High-Density Pin Configurations

Nano-D connectors come with high-density pin configurations, allowing for more connections in a smaller area. This capability is particularly beneficial in applications where multiple circuits need to be connected without expanding the overall size of the device.

3. Key Applications of Nano-D Airtight Connectors

The applications of Nano-D airtight connectors span various industries, each benefiting from their unique design and robust performance.

3.1 Aerospace Industry

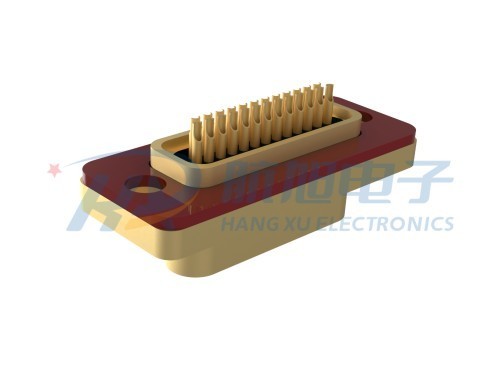

In aerospace, connectors face extreme temperature variations and pressure changes. Nano-D connectors ensure reliable connectivity, critical for navigation and communication systems.

3.2 Medical Devices

In the medical field, equipment must operate flawlessly under strict hygiene and environmental conditions. Nano-D connectors provide the necessary reliability and durability for devices such as diagnostic and imaging equipment.

3.3 Military Applications

Military operations demand connectors that can perform under extreme conditions. The resistance to shock, vibration, and environmental stress makes Nano-D connectors ideal for use in tactical communication equipment and unmanned vehicles.

3.4 Industrial Automation

In industrial settings, machinery and equipment are often subjected to dust, moisture, and mechanical wear. The robustness of Nano-D connectors helps to maintain operational efficiency and reduce downtime.

4. Benefits of Using Nano-D Airtight Connectors

The advantages of using Nano-D connectors extend beyond their basic functionality. Here’s why industries are increasingly opting for these advanced connectors:

4.1 Enhanced Reliability

With their airtight seals and robust construction, Nano-D connectors significantly enhance the reliability of systems operating in harsh environments. This reliability translates into less frequent maintenance and reduced operational costs.

4.2 Improved Performance

These connectors maintain signal integrity even under extreme conditions. Their design minimizes the risk of signal loss, ensuring that critical data is transmitted accurately.

4.3 Cost-Effectiveness

While the initial investment in Nano-D connectors can be higher than traditional options, their longevity and durability can lead to significant savings over time. Fewer replacements and reduced maintenance costs contribute to overall cost-effectiveness.

4.4 Versatility

Nano-D connectors are adaptable to various applications, making them suitable for diverse industries. Their ability to withstand extreme conditions means they can be utilized in numerous settings without compromising performance.

5. Performance in Extreme Conditions

Nano-D airtight connectors excel in environments characterized by extreme temperatures, humidity, and mechanical stress.

5.1 Temperature Resistance

These connectors can function effectively in temperature ranges from -55°C to +125°C. This wide range of operation ensures that they can be used in diverse environments, from the frozen tundra to the scorching desert.

5.2 Humidity and Water Resistance

The airtight sealing technology prevents moisture ingress, making Nano-D connectors suitable for applications where exposure to liquids is a concern. Their high IP ratings ensure that they can withstand high humidity and water exposure.

5.3 Mechanical Durability

Nano-D connectors are designed to endure mechanical stress. They can withstand significant vibration and shock, ensuring continuous operation even in demanding conditions.

6. Comparison with Traditional Connectors

To appreciate the benefits of Nano-D connectors fully, it’s essential to compare them with traditional connector types.

6.1 Size and Weight

Traditional connectors often occupy more space and are heavier, making them less suitable for modern applications requiring compactness. In contrast, Nano-D connectors provide high-density connections in a smaller footprint.

6.2 Sealing Capabilities

Many traditional connectors lack the advanced sealing technology found in Nano-D connectors, making them more susceptible to environmental factors. This can lead to higher failure rates and increased maintenance.

6.3 Signal Integrity

Traditional connectors may struggle with signal integrity, especially in extreme conditions. Nano-D connectors, with their precision engineering, minimize signal loss even under challenging circumstances.

7. The Future of Nano-D Connectors in Technology

The evolution of technology continues to drive innovation in connector design. As industries demand greater reliability and performance, **Nano-D connectors represent the future of connectivity solutions**.

7.1 Growing Demand in IoT

As the Internet of Things (IoT) expands, the need for reliable and durable connectors will grow. Nano-D connectors are well-positioned to meet the demands of IoT applications, where connectivity is crucial.

7.2 Advancements in Materials

Research into new materials will likely lead to even more robust and efficient Nano-D connectors. Innovations may enhance their performance, making them suitable for even more extreme applications.

7.3 Integration with Emerging Technologies

With the rise of technologies like AI and machine learning, connectors will need to become smarter and more adaptable. Nano-D connectors could integrate with these technologies to provide real-time diagnostics and performance monitoring.

8. FAQs about Nano-D Airtight Connectors

8.1 What are Nano-D connectors used for?

Nano-D connectors are primarily used in industries like aerospace, medical devices, military, and industrial automation, where reliability under harsh conditions is essential.

8.2 How do Nano-D connectors achieve airtight sealing?

They utilize advanced sealing technologies, such as O-rings and potting compounds, to prevent moisture and contaminants from entering.

8.3 Are Nano-D connectors compatible with traditional connector types?

Yes, many Nano-D connectors are designed to interface with conventional connectors, making them versatile for various applications.

8.4 What is the typical lifespan of a Nano-D connector?

With proper handling and installation, Nano-D connectors can last many years, significantly longer than traditional connectors in harsh environments.

8.5 How do Nano-D connectors compare in cost to traditional connectors?

While they may have a higher upfront cost, the long-term savings from reduced maintenance and replacements often make them more cost-effective over time.

9. Conclusion

In conclusion, **Nano-D airtight connectors represent a significant advancement in connectivity technology**, particularly for applications in harsh environments. Their durability, reliability, and performance in extreme conditions make them an ideal choice for various industries. As technology continues to evolve, the capabilities of Nano-D connectors will undoubtedly expand, further solidifying their place as a critical component in modern electronic systems. Investing in Nano-D connectors means investing in the future of reliable connectivity.

Related Documents

Related News