-

-

Nano-D ConnectorsMicro-D ConnectorsNano Circular ConnectorsMicro Circular ConnectorsHigh Speed ConnectorsReetangular ConnectorsPCB Mount ConnectorsAirtight ConnectorsRF ConnectorsCable AssembliesElectronic Control Module

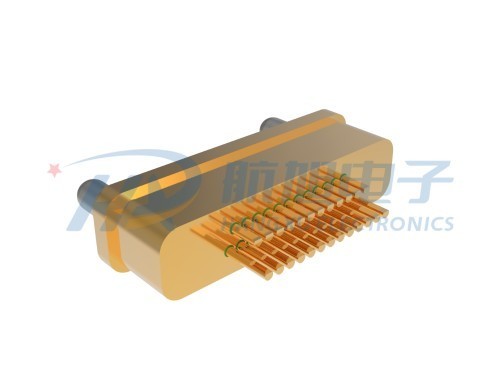

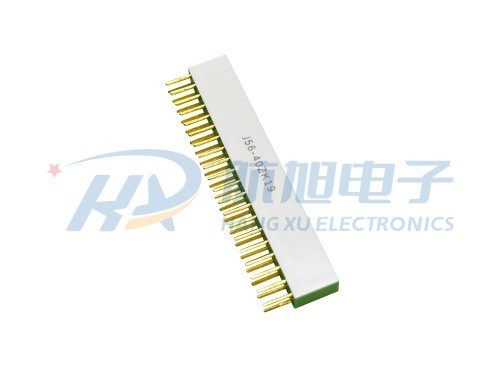

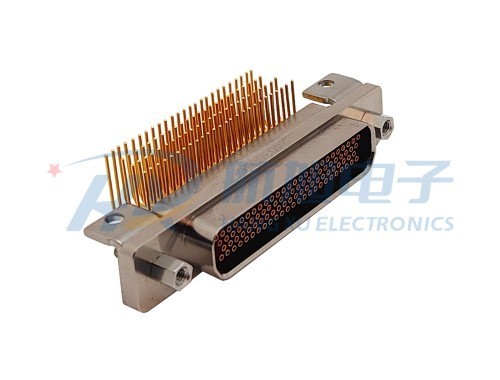

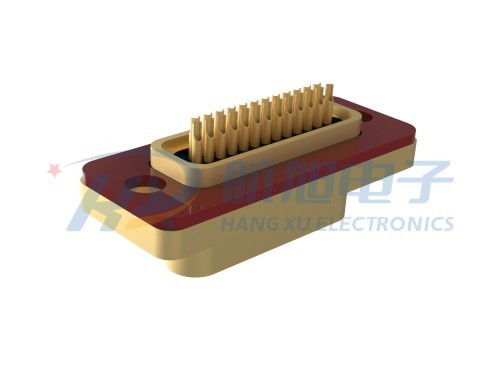

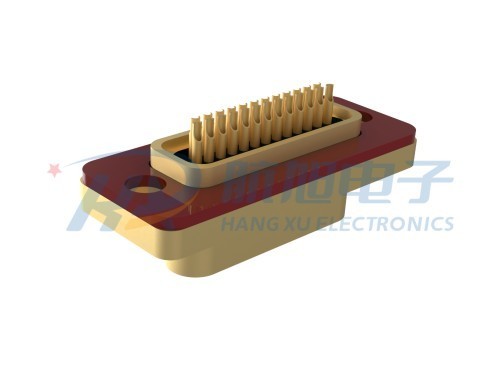

J30JZ Compact Micro-D Connectors

J30JZ Compact Micro-D Connectors J30J Micro-D Connectors

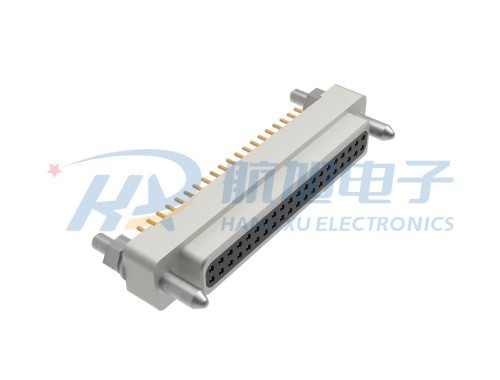

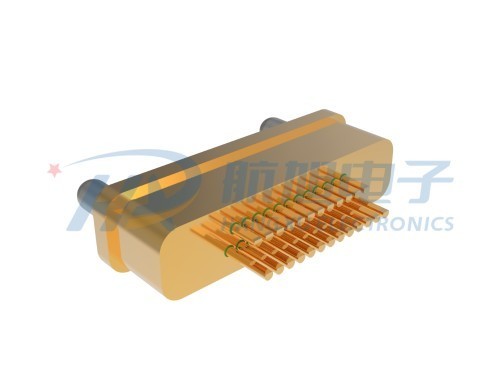

J30J Micro-D Connectors J20J Micro-D Connectors

J20J Micro-D Connectors J29A Micro-D Connectors

J29A Micro-D Connectors MDM1 Micro-D Connectors

MDM1 Micro-D Connectors MDC1 Micro-D Electrical Connector

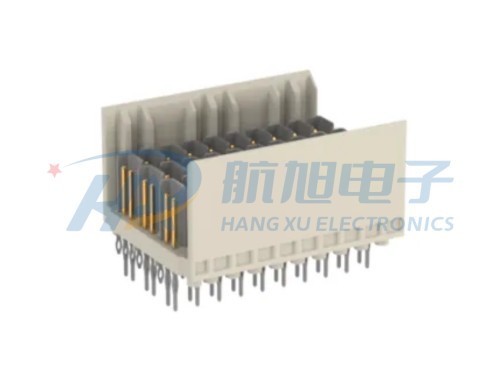

MDC1 Micro-D Electrical Connector HJ30J High-Speed Micro-D Connectors

HJ30J High-Speed Micro-D Connectors J30JM Hermetic Sealed Micro-D Connectors

J30JM Hermetic Sealed Micro-D Connectors J30JM1 Gas Sealed Micro-D Connectors

J30JM1 Gas Sealed Micro-D Connectors J30JB Micro-D Connectors

J30JB Micro-D Connectors J30JMI Gas Sealed Micro-D Connectors

J30JMI Gas Sealed Micro-D Connectors J63AM Micro Electrical Connector

J63AM Micro Electrical Connector J30JM Hermetic Sealed Micro-D Connectors

J30JM Hermetic Sealed Micro-D Connectors J30JM1 Gas Sealed Micro-D Connectors

J30JM1 Gas Sealed Micro-D Connectors J30JMI Gas Sealed Micro-D Connectors

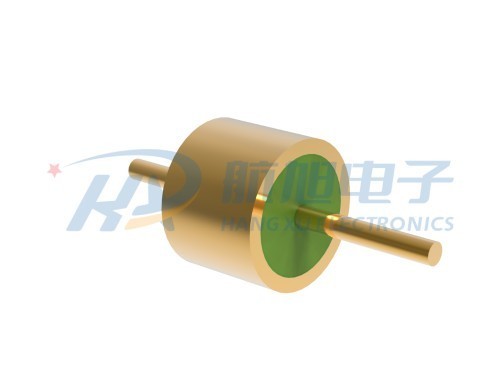

J30JMI Gas Sealed Micro-D Connectors DC Single Core Insulator

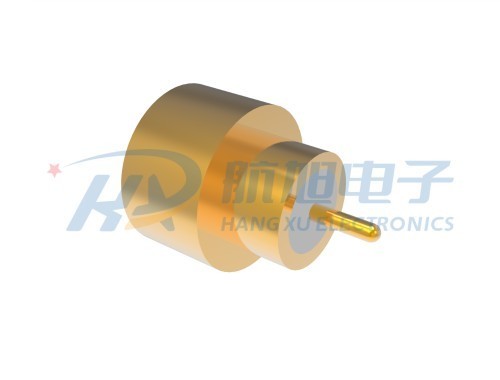

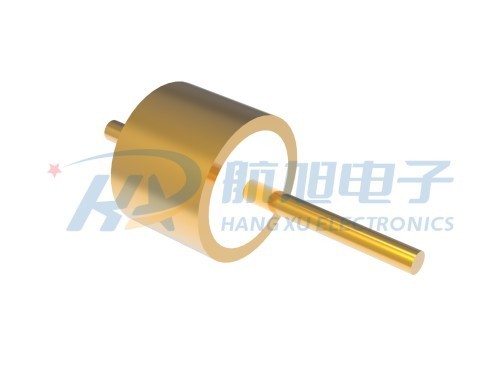

DC Single Core Insulator DC insulator series

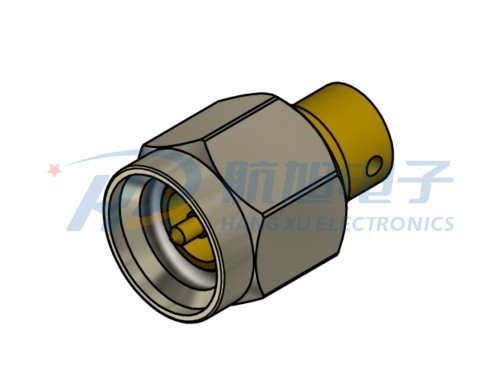

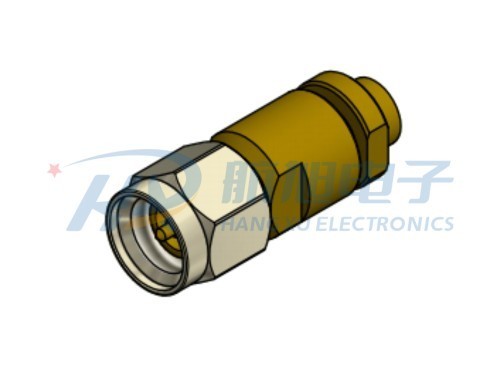

DC insulator series SMP(M)

SMP(M) RF insulator

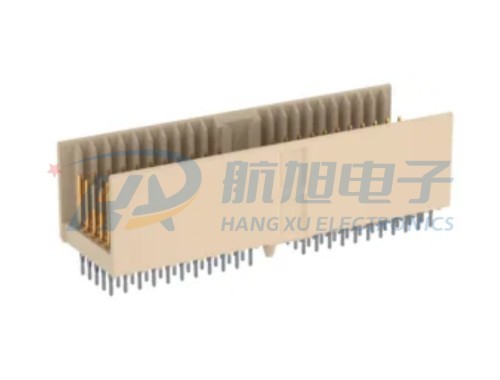

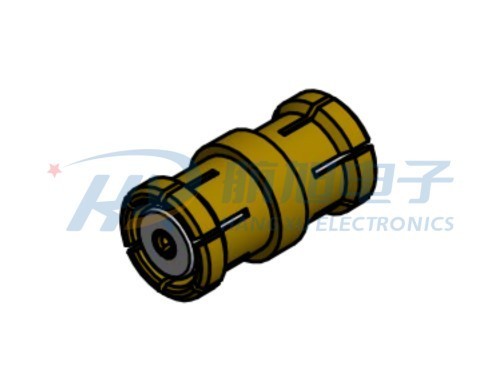

RF insulator MDCS tandem

MDCS tandem Metal sealing

Metal sealing -

-

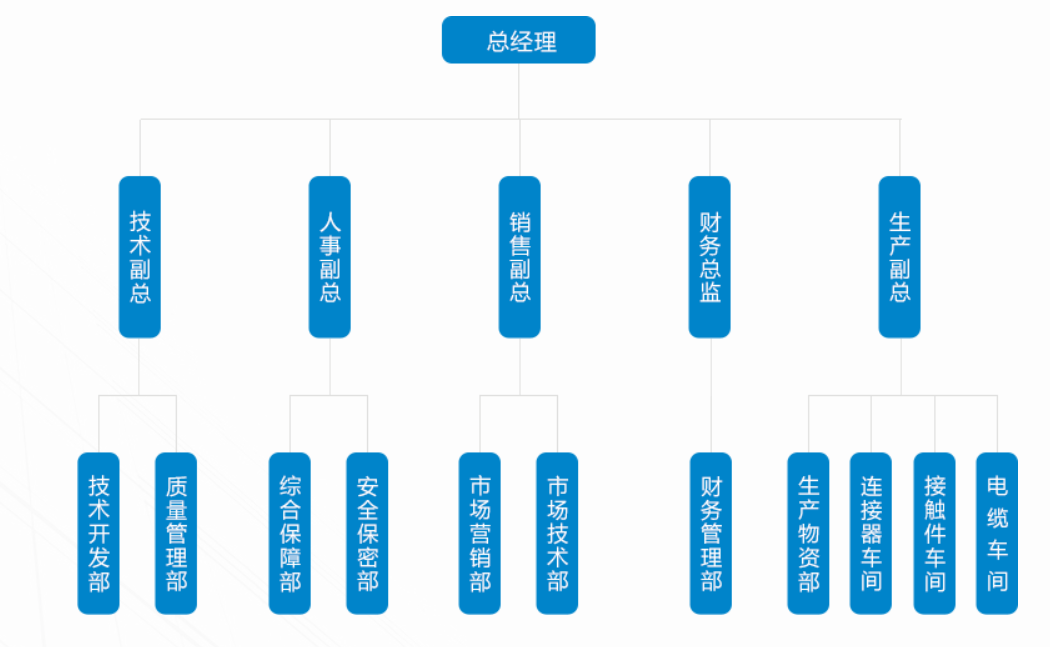

Hangxu electronic Technology

In 2022, it was recognized as a high-tech enterprise by Guizhou Province

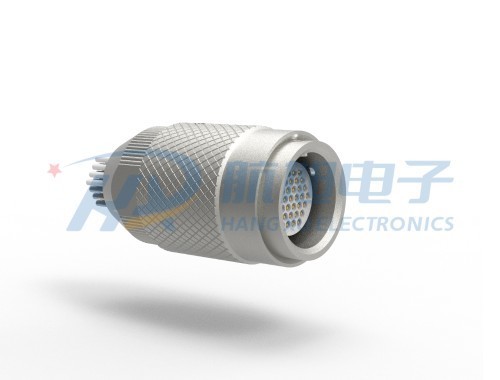

Understanding Airtight Connectors: Essential Components for Reliable Electrical Connections

2025-05-03

Airtight connectors are specialized electrical connectors designed to maintain a sealed environment, preventing the ingress of moisture, dust, and other contaminants that could adversely affect the performance of electrical systems. Their construction typically involves robust materials and precise engineering to create an effective barrier against external environmental factors.

One of the primary applications of airtight connectors is in outdoor and industrial settings where equipment is exposed to harsh conditions. For instance, in marine, automotive, and aerospace industries, the integrity of electrical connections is paramount. Any exposure to moisture can lead to corrosion, short circuits, and potentially catastrophic failures. Airtight connectors mitigate these risks by providing a reliable seal that protects the internal components from external elements.

When considering airtight connectors, it is essential to evaluate several factors to ensure you select the right type for your specific application. One important aspect is the connector's ingress protection (IP) rating, which indicates its level of resistance to dust and water. IP ratings are typically presented as two digits, where the first digit represents protection against solid objects (like dust), and the second digit indicates protection against liquids. For example, an IP67 rating means that the connector is fully dust-tight and can withstand immersion in water up to 1 meter for a limited duration.

Another consideration is the material used in the construction of the connector. Common materials include thermoplastics, metals, and silicone rubber, each offering different benefits regarding durability, flexibility, and resistance to environmental factors. For example, silicone rubber is often favored for its high resistance to temperature fluctuations and its ability to maintain elasticity, making it an excellent choice for applications subject to thermal expansion and contraction.

Furthermore, it's vital to understand the connection mechanism of the airtight connector. Some connectors utilize a screw-locking or snap-fit design to ensure a secure connection, while others may feature a push-pull mechanism for ease of use. Selecting the appropriate connection style can significantly impact the efficiency and reliability of the electrical system.

In conclusion, airtight connectors play a pivotal role in safeguarding electrical connections in challenging environments. By carefully considering factors such as ingress protection ratings, material selection, and connection mechanisms, professionals can ensure that their electrical systems remain operational and reliable, regardless of external conditions. Understanding these components empowers individuals to make informed decisions, enhancing the performance and longevity of their electrical applications.

One of the primary applications of airtight connectors is in outdoor and industrial settings where equipment is exposed to harsh conditions. For instance, in marine, automotive, and aerospace industries, the integrity of electrical connections is paramount. Any exposure to moisture can lead to corrosion, short circuits, and potentially catastrophic failures. Airtight connectors mitigate these risks by providing a reliable seal that protects the internal components from external elements.

When considering airtight connectors, it is essential to evaluate several factors to ensure you select the right type for your specific application. One important aspect is the connector's ingress protection (IP) rating, which indicates its level of resistance to dust and water. IP ratings are typically presented as two digits, where the first digit represents protection against solid objects (like dust), and the second digit indicates protection against liquids. For example, an IP67 rating means that the connector is fully dust-tight and can withstand immersion in water up to 1 meter for a limited duration.

Another consideration is the material used in the construction of the connector. Common materials include thermoplastics, metals, and silicone rubber, each offering different benefits regarding durability, flexibility, and resistance to environmental factors. For example, silicone rubber is often favored for its high resistance to temperature fluctuations and its ability to maintain elasticity, making it an excellent choice for applications subject to thermal expansion and contraction.

Furthermore, it's vital to understand the connection mechanism of the airtight connector. Some connectors utilize a screw-locking or snap-fit design to ensure a secure connection, while others may feature a push-pull mechanism for ease of use. Selecting the appropriate connection style can significantly impact the efficiency and reliability of the electrical system.

In conclusion, airtight connectors play a pivotal role in safeguarding electrical connections in challenging environments. By carefully considering factors such as ingress protection ratings, material selection, and connection mechanisms, professionals can ensure that their electrical systems remain operational and reliable, regardless of external conditions. Understanding these components empowers individuals to make informed decisions, enhancing the performance and longevity of their electrical applications.

Related Documents

Related News

Hotline/WhatsApp:+86-185-8685-2255

Hotline:

Address: No. 6, Xiaomeng Industrial Park, Economic Development Zone, Guiyang City, Guizhou, China

Official Website

WeChat Customer Service

SAF Coolest v1.3 设置面板 TUQSD-ZDBH-ZXSSE-ASE

图片ALT信息: Guizhou Hangxu Electronic Technology

违禁词: First, best, first-class, leading, unique, king, leader, leader, extreme,

无数据提示

Sorry, the current column has no content for the time being.!

You can view other columns or returnHome Page