Essential Tips for Maintaining High-Speed Micro-D Connectors to Ensure Optimal Performance

2025-05-28

Essential Tips for Maintaining High-Speed Micro-D Connectors to Ensure Optimal Performance

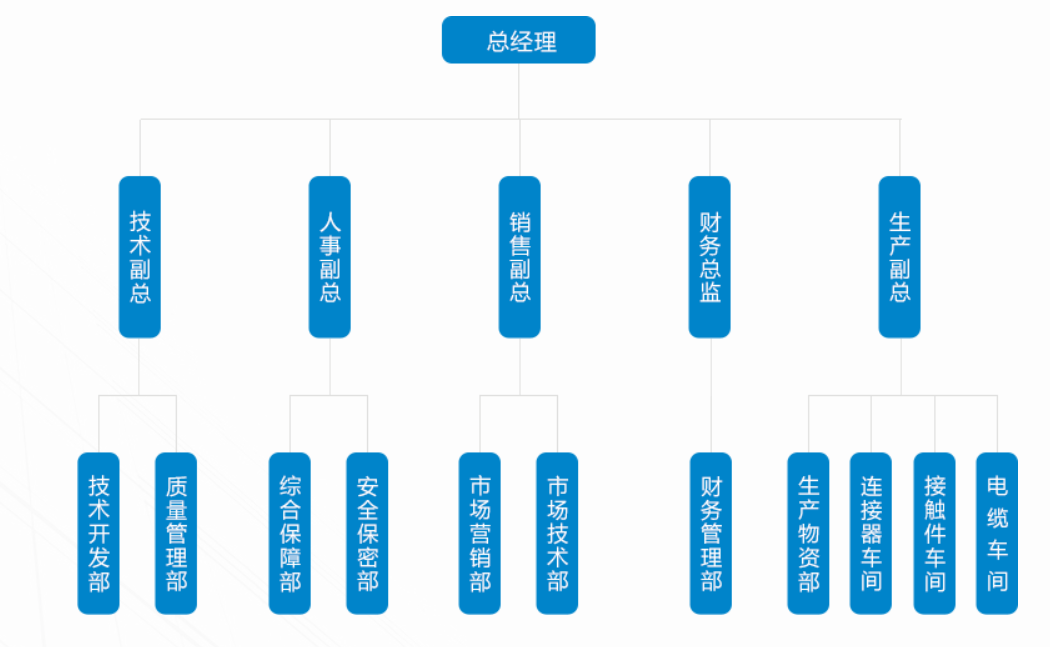

Table of Contents

- 1. Understanding High-Speed Micro-D Connectors

- 2. Importance of Maintaining Micro-D Connectors

- 3. Common Issues Faced with Micro-D Connectors

- 4. Routine Inspections: Key to Longevity

- 5. Cleaning Procedures for Optimal Function

- 6. Environmental Factors Affecting Performance

- 7. Proper Storage and Handling Techniques

- 8. When to Seek Professional Assistance

- 9. Conclusion

- 10. Frequently Asked Questions

1. Understanding High-Speed Micro-D Connectors

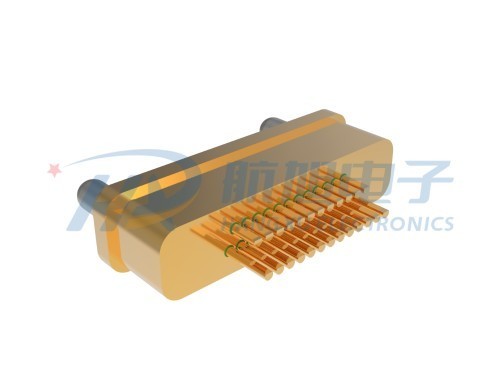

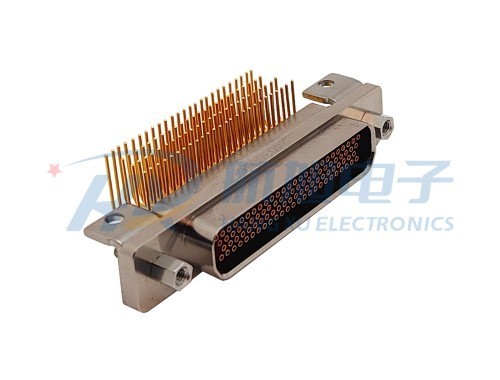

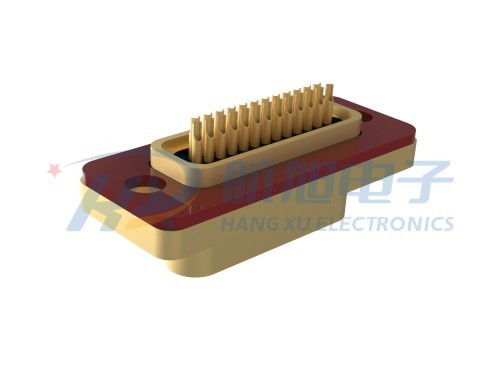

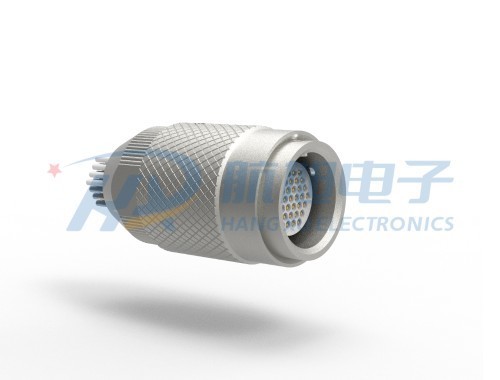

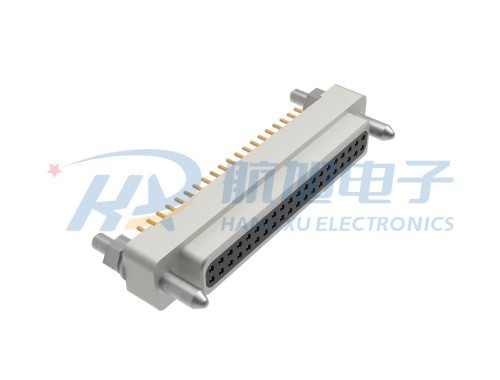

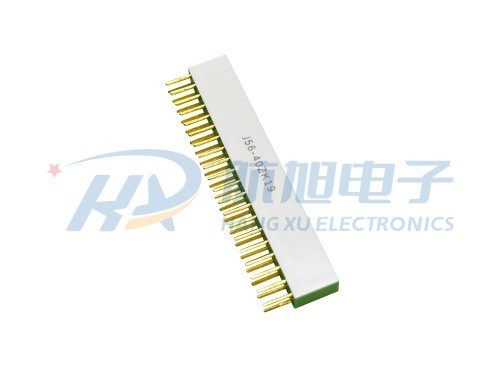

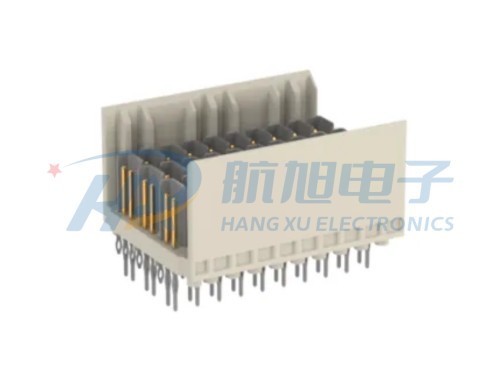

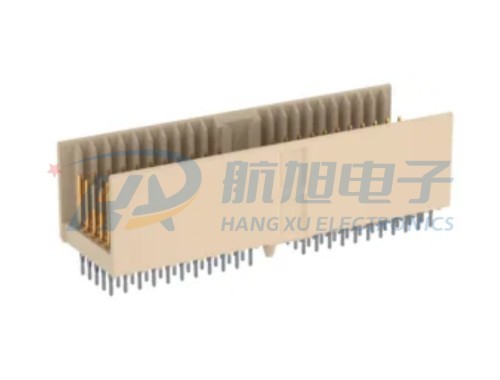

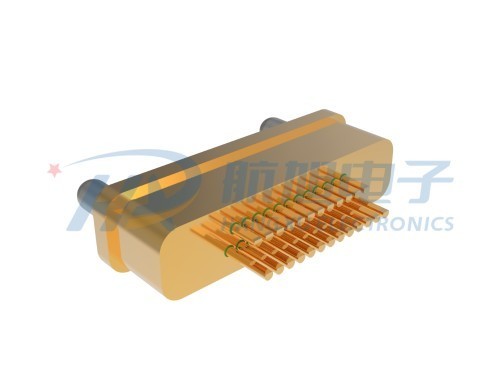

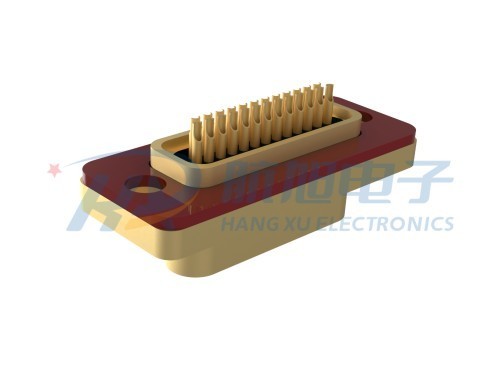

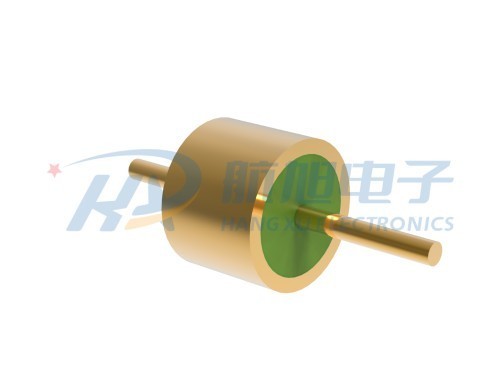

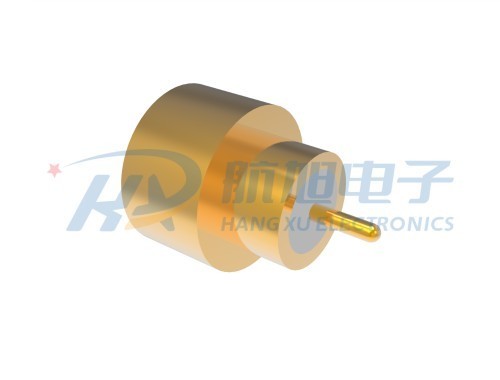

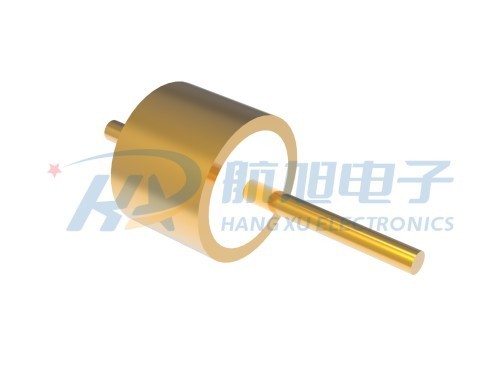

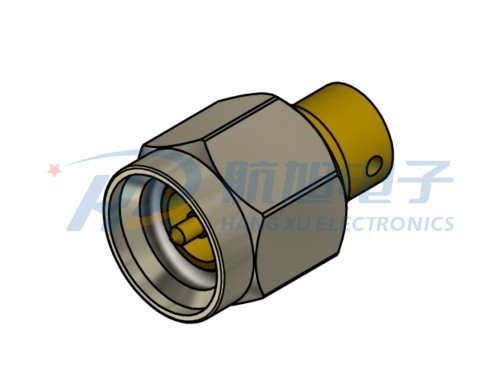

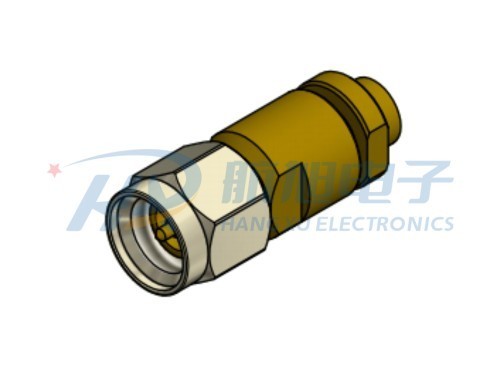

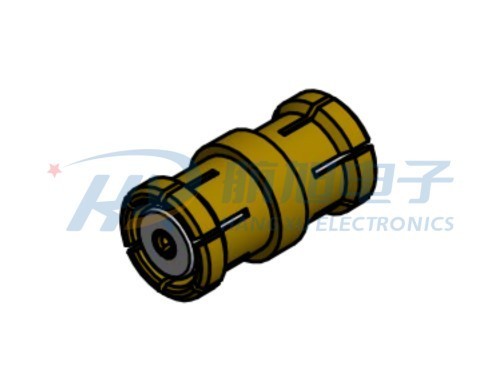

High-speed Micro-D connectors play a crucial role in various industries, including telecommunications, aerospace, and medical applications. These connectors are designed to provide a reliable connection while facilitating high-speed data transfer. Understanding the construction and functionality of Micro-D connectors is essential for maintaining their performance.

Micro-D connectors feature a compact design and are characterized by their durability and lightweight nature. They typically consist of multiple pins and sockets, allowing for connections that are both secure and efficient. The precision engineering involved in their production ensures that they meet stringent performance standards, making them ideal for high-speed applications.

2. Importance of Maintaining Micro-D Connectors

Maintaining Micro-D connectors is vital for ensuring the longevity and optimal performance of electronic devices. Neglecting regular maintenance can lead to various issues, including signal loss, data corruption, and physical damage. By implementing effective maintenance strategies, we can significantly reduce the risk of failure and enhance the reliability of our connections.

Furthermore, high-speed Micro-D connectors are often used in critical applications where performance is paramount. Any degradation in connection quality can have severe consequences, such as operational downtime or safety hazards. Therefore, adopting a proactive maintenance approach is essential.

3. Common Issues Faced with Micro-D Connectors

Several issues can arise with Micro-D connectors that affect their performance:

Physical Damage

Physical damage can occur due to mishandling or environmental factors. Bending, cracking, or breaking of the connector can compromise the connection.

Corrosion

Corrosion is a common problem, particularly in humid environments. Moisture can lead to rust formation on metallic components, affecting conductivity.

Contamination

Dust, dirt, and other contaminants can accumulate on connector surfaces, leading to poor electrical connections and signal loss.

4. Routine Inspections: Key to Longevity

Implementing routine inspections is crucial for identifying potential issues before they escalate. During these inspections, we recommend checking for:

Visual Checks

Conduct visual inspections to detect any signs of physical damage, corrosion, or contamination. Pay close attention to the integrity of pins and sockets.

Connection Integrity

Test the connection integrity by measuring resistance levels. Any significant deviations from normal values may indicate underlying issues.

5. Cleaning Procedures for Optimal Function

Regular cleaning is essential for maintaining the performance of Micro-D connectors. We recommend the following cleaning procedures:

Using Appropriate Cleaning Solutions

Utilize isopropyl alcohol or specialized electronic cleaning solutions to gently clean contacts and surfaces. Avoid using abrasive materials that could scratch or damage the connectors.

Cleaning Frequency

Establish a cleaning schedule based on the environmental conditions and frequency of use. For applications in dust-prone areas, more frequent cleaning will be necessary.

Cleaning Steps

1. Power down all connected equipment.

2. Dampen a lint-free cloth with the cleaning solution.

3. Wipe the connector surfaces gently, ensuring all crevices are clean.

4. Allow the connectors to dry completely before re-establishing connections.

6. Environmental Factors Affecting Performance

Several environmental factors can affect the performance of Micro-D connectors. Understanding these factors allows us to implement protective measures.

Humidity and Moisture

High humidity levels can lead to corrosion and contamination. Ensure that connectors are rated for moisture resistance if used in such environments.

Temperature Extremes

Extreme temperatures can cause thermal expansion and contraction, potentially leading to physical damage. Choose connectors that are designed to operate within the required temperature range.

Vibration and Shock

In applications involving significant vibration or shock, proper mounting and securing techniques are essential to prevent physical damage to connectors.

7. Proper Storage and Handling Techniques

Proper storage and handling techniques can significantly impact the longevity of Micro-D connectors.

Storage Conditions

Store connectors in a clean, dry environment, away from extreme temperatures and moisture. Utilize anti-static bags for additional protection against electrostatic discharge.

Handling Procedures

When handling connectors, always grasp the housing rather than the pins to avoid bending or damaging them. Employ anti-static wristbands when working with sensitive electronic components.

8. When to Seek Professional Assistance

While many maintenance tasks can be performed in-house, there are times when seeking professional assistance is advisable.

Complex Repairs

If connectors exhibit complex issues, such as internal damage or severe corrosion, it is best to consult a professional. Attempting repairs without the necessary expertise can lead to further damage.

Upgrades and Replacements

When considering upgrades or replacements, consulting a specialist is essential to ensure compatibility and optimal performance.

9. Conclusion

Maintaining high-speed Micro-D connectors is essential for ensuring their optimal performance and longevity. By implementing routine inspections, cleaning procedures, and understanding environmental factors, we can significantly enhance the reliability of these critical connections. Proper storage and handling techniques further contribute to the durability of Micro-D connectors. When in doubt, do not hesitate to seek professional assistance to address complex issues.

10. Frequently Asked Questions

What are Micro-D connectors used for?

Micro-D connectors are commonly used in high-speed applications across various industries, including telecommunications, aerospace, and medical devices.

How often should Micro-D connectors be cleaned?

The cleaning frequency depends on the environmental conditions and usage. In dusty or humid environments, more frequent cleaning is recommended.

Can I repair damaged Micro-D connectors myself?

Minor surface cleaning can be done in-house, but complex repairs should be left to professionals to avoid further damage.

What are the signs that a Micro-D connector is failing?

Common signs include intermittent connectivity issues, visible corrosion, or physical damage to pins and sockets.

Are there specific cleaning solutions recommended for Micro-D connectors?

Yes, isopropyl alcohol or specialized electronic cleaning solutions are recommended for safely cleaning Micro-D connectors without causing damage.

Related Documents

Related News