Enhancing Operations: Military Cable Assemblies Unleashed

2025-06-09

Enhancing Operations: Military Cable Assemblies Unleashed

Table of Contents

- 1. Introduction to Military Cable Assemblies

- 2. The Importance of Cable Assemblies in Military Operations

- 3. Designing Military Cable Assemblies

- 4. Types of Military Cable Assemblies

- 5. Applications of Military Cable Assemblies

- 6. Challenges in Military Cable Assembly Manufacturing

- 7. The Future of Military Cable Assemblies

- 8. Frequently Asked Questions

- 9. Conclusion

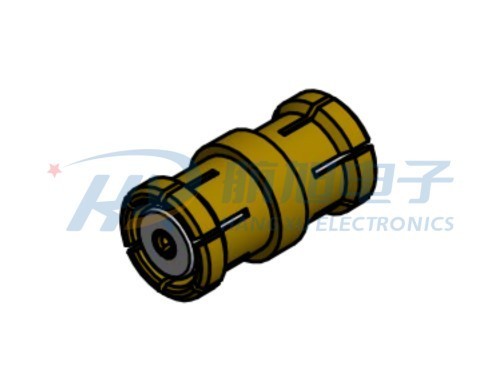

1. Introduction to Military Cable Assemblies

Military cable assemblies play a crucial role in ensuring the seamless operation of various defense systems. These assemblies are specifically designed to withstand the rigorous conditions of military environments, which can include extreme temperatures, vibration, and exposure to moisture or chemicals. As technology evolves, so do the requirements for these assemblies, pushing manufacturers to innovate continually.

2. The Importance of Cable Assemblies in Military Operations

In the defense sector, reliability and efficiency are paramount. **Military cable assemblies** serve as the backbone of communication, power distribution, and data transfer among various military systems. Failures in these assemblies can lead to significant operational setbacks, compromising mission success. Thus, the design and manufacturing of these assemblies must adhere to the highest standards of quality.

Boosting Communication and Coordination

Effective communication is essential for military operations. Cable assemblies facilitate real-time data transfer between command centers and field units, allowing for quick decision-making and enhanced coordination during missions.

Power Supply Reliability

Military vehicles and equipment require a consistent power supply. High-quality cable assemblies ensure that power is reliably delivered to critical systems, minimizing the risk of failure during crucial moments.

3. Designing Military Cable Assemblies

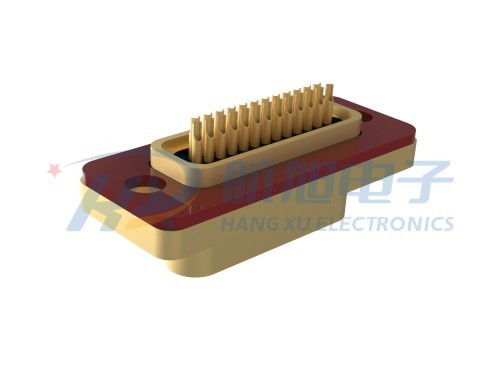

Designing military cable assemblies involves a thorough understanding of both the technical specifications and the operational environment. Manufacturers must consider factors such as weight, flexibility, and resistance to environmental hazards.

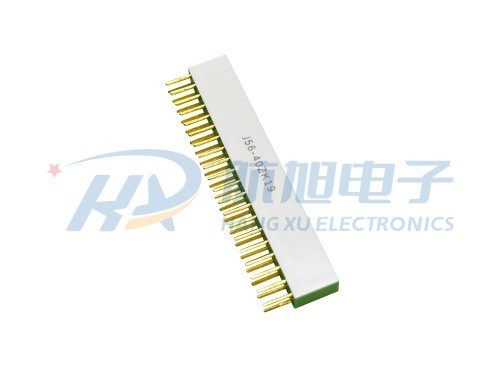

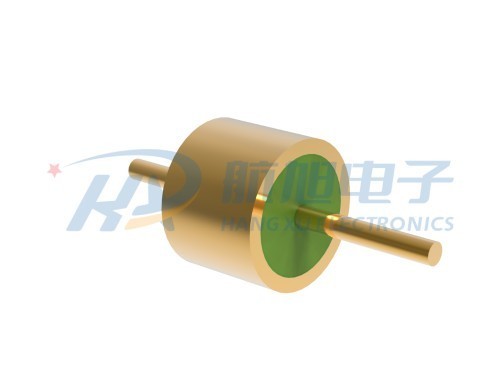

3.1. Materials Used in Military Cable Assemblies

The materials chosen for military cable assemblies significantly impact their performance. Some commonly used materials include:

- **Copper and Aluminum:** Conductive materials that provide efficient electrical transmission.

- **Polyurethane and PVC:** Insulating materials that offer protection against abrasion and chemical exposure.

- **Teflon:** Used for its high-temperature resistance and low friction properties.

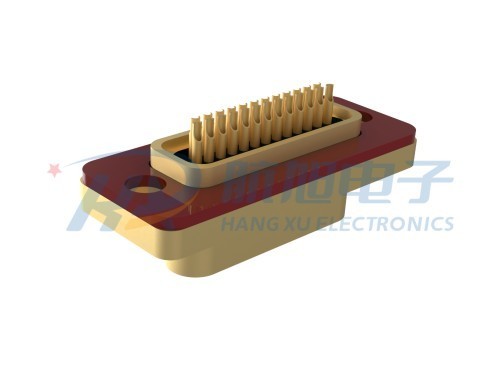

3.2. Military Standards and Compliance

Military cable assemblies must comply with various military standards, such as MIL-STD-810 for environmental testing and MIL-STD-1276 for electrical connectors. Adhering to these standards ensures that the assemblies can withstand the specific challenges of military operations.

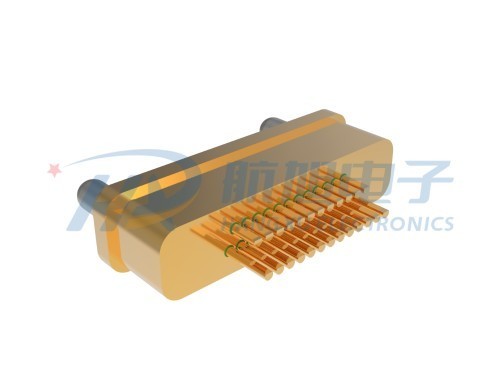

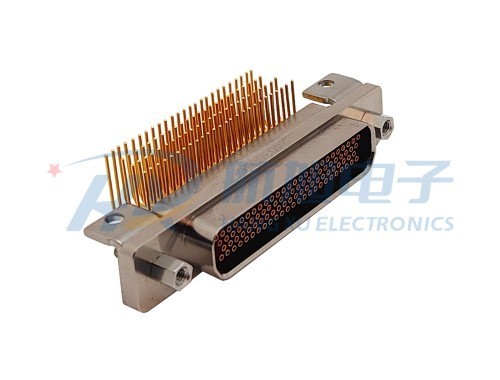

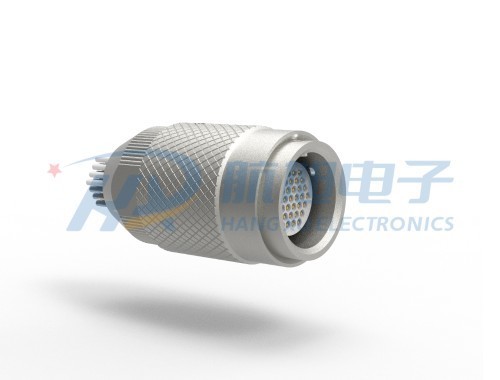

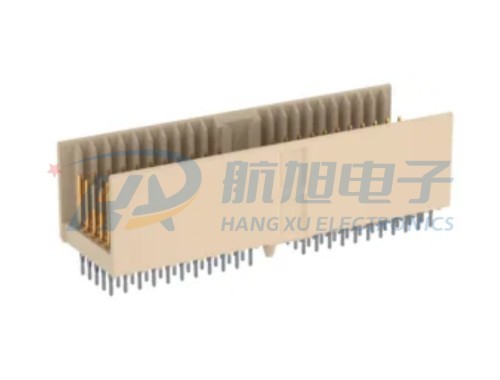

4. Types of Military Cable Assemblies

Military cable assemblies come in various forms, each tailored for specific applications. Understanding these types is crucial for selecting the right assembly for a given task.

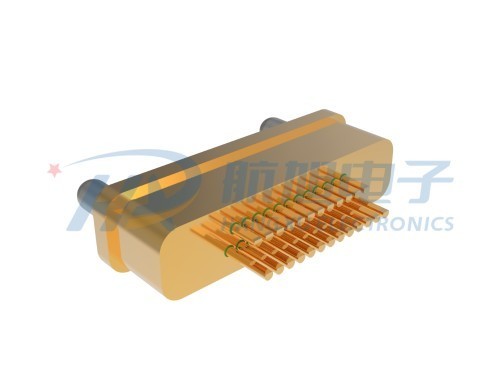

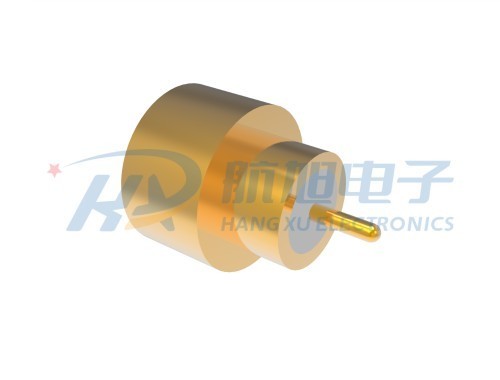

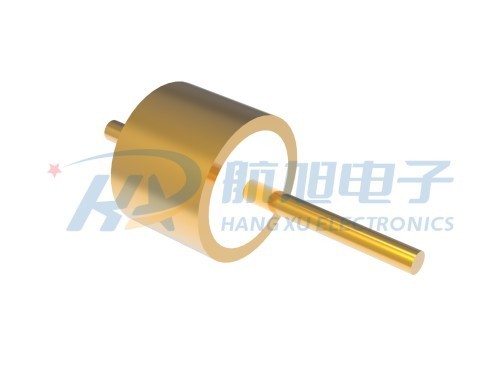

4.1. Power Cable Assemblies

Power cable assemblies are designed to deliver electrical power to military equipment and vehicles. They are often built to handle high voltages and currents, ensuring that critical systems receive the necessary power without interruption.

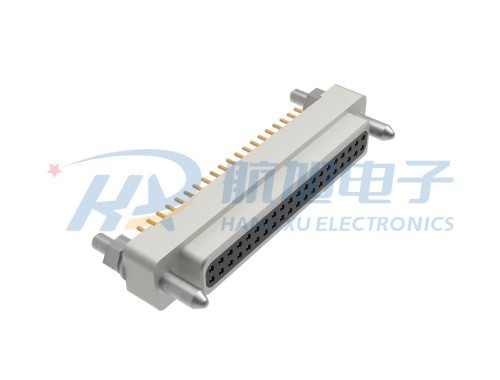

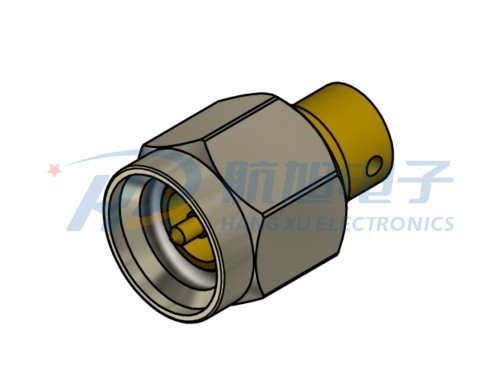

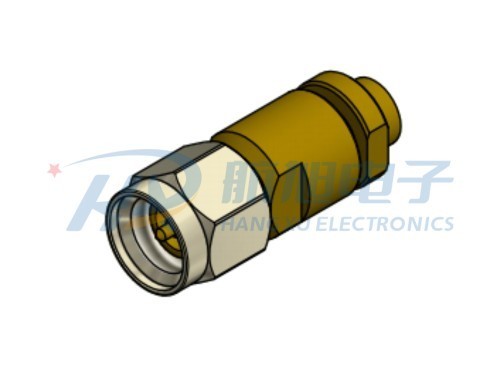

4.2. Data Cable Assemblies

Data cable assemblies facilitate the transfer of information between devices. These assemblies can include Ethernet cables, fiber optics, and other data transmission mediums that support high-speed communication.

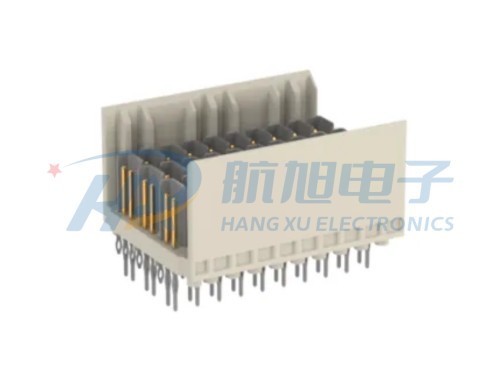

4.3. Hybrid Cable Assemblies

Hybrid cable assemblies combine power and data capabilities into a single assembly. This design reduces the number of cables required, streamlining installations and saving weight in mobile applications.

5. Applications of Military Cable Assemblies

Military cable assemblies are utilized across various applications, reflecting their versatility and essential role in defense operations.

Communication Systems

Robust cable assemblies are critical for maintaining communication networks, linking radios, satellite systems, and tactical devices.

Weapon Systems

Cable assemblies are fundamental to the operation of various weapon systems, ensuring reliable power and data transfer between components.

Transport and Logistics

Military vehicles rely on specialized cable assemblies for power and communication, enabling efficient operation in the field and during transport.

6. Challenges in Military Cable Assembly Manufacturing

Manufacturers face numerous challenges in producing military cable assemblies, including:

- **Complex Specifications:** Meeting stringent military standards can be complex and time-consuming.

- **Environmental Hazards:** Ensuring the assemblies are resistant to extreme conditions adds another layer of complexity.

- **Supply Chain Issues:** Access to high-quality materials can be limited, impacting production timelines.

7. The Future of Military Cable Assemblies

The future of military cable assemblies is poised for innovation, driven by advancements in materials science and technology. Emerging trends include:

- **Lightweight Materials:** The use of advanced composites can reduce weight while maintaining durability.

- **Smart Cable Assemblies:** Integrating sensors into cable assemblies can provide real-time monitoring of performance and conditions.

- **Sustainable Practices:** There is a growing emphasis on environmentally friendly manufacturing processes.

8. Frequently Asked Questions

What are military cable assemblies used for?

Military cable assemblies are used for power distribution, data transfer, and communication between various military systems and equipment.

How are military cable assemblies different from civilian versions?

Military cable assemblies are designed to meet stringent standards for durability, environmental resistance, and reliability, which are typically more rigorous than civilian standards.

What materials are commonly used in military cable assemblies?

Common materials include copper, aluminum, polyurethane, PVC, and Teflon, chosen for their electrical and environmental properties.

How do military standards affect cable assembly design?

Military standards dictate the requirements for performance, durability, and safety that must be met by military cable assemblies, influencing every aspect of their design and manufacturing.

What are the future trends in military cable assembly technology?

Future trends include the use of lightweight materials, the integration of smart technologies, and a focus on sustainable manufacturing practices.

9. Conclusion

Military cable assemblies are vital components that enhance operational efficiency and reliability in defense applications. As technology continues to advance, the design and manufacturing of these assemblies must evolve to meet the changing needs of modern military operations. By understanding the various types, materials, and applications of military cable assemblies, stakeholders can make informed decisions that contribute to mission success. Investing in high-quality cable assemblies ensures that military forces remain prepared and capable in an ever-changing global landscape.

Related Documents

Related News