Day 58: Unraveling the Versatility of High Voltage Connectors

2025-06-23

Day 58: Unraveling the Versatility of High Voltage Connectors

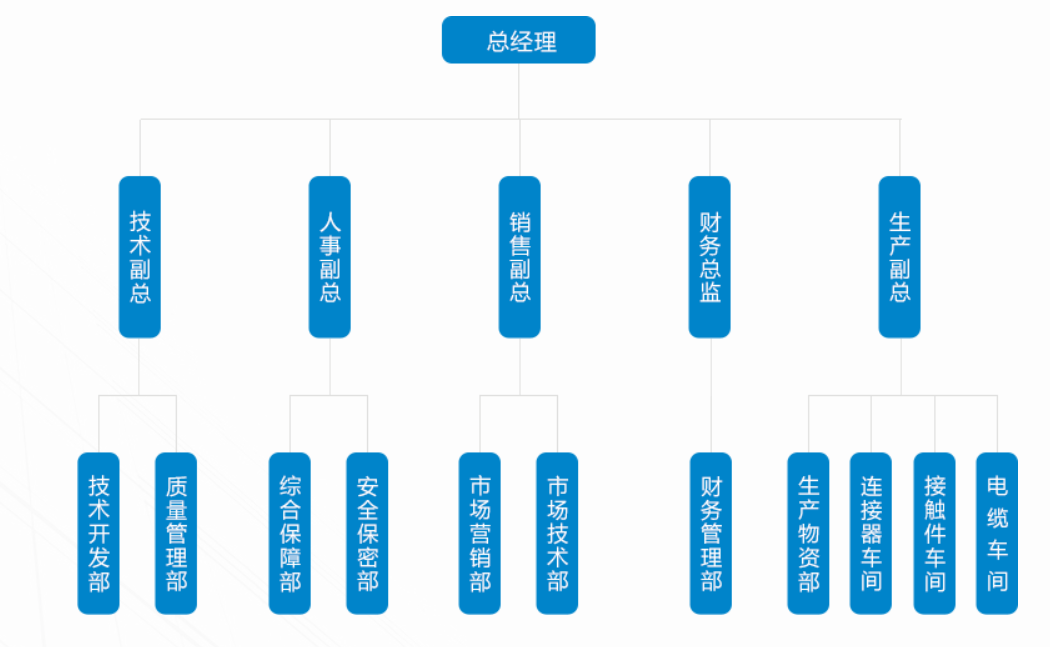

Table of Contents

- Introduction to High Voltage Connectors

- Importance of High Voltage Connectors

- Applications of High Voltage Connectors

- Types of High Voltage Connectors

- Advantages of Using High Voltage Connectors

- Challenges in High Voltage Connector Design

- Future of High Voltage Connectors

- Conclusion

- FAQs

Introduction to High Voltage Connectors

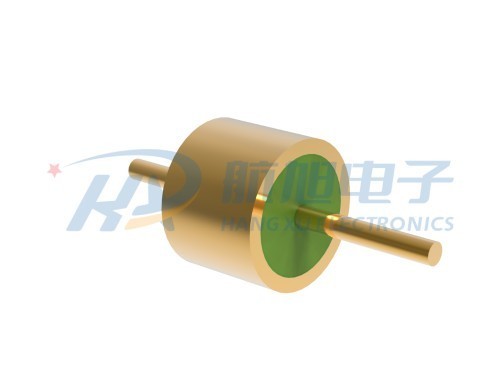

High voltage connectors are vital components designed to establish electrical connections in systems that operate at voltages exceeding 1,000 volts (V). These connectors play a crucial role in ensuring safety and performance in various applications, including power generation, distribution, and industrial control systems. Understanding their functionality and versatility is key to leveraging their benefits across multiple industries.

Importance of High Voltage Connectors

The significance of high voltage connectors cannot be overstated. They offer a reliable means of managing high electrical currents while minimizing the risks associated with arcing, overheating, and electrical failures. High voltage connectors are engineered with advanced materials and designs to provide optimal insulation, mechanical strength, and thermal performance, making them indispensable in demanding environments.

In an era where energy efficiency and reliability are paramount, the role of high voltage connectors in electrical systems is more critical than ever. They not only facilitate the safe transmission of power but also enhance the overall efficiency of electrical systems, reducing energy loss and improving performance.

Applications of High Voltage Connectors

High voltage connectors find applications across various sectors, each capitalizing on their unique features and benefits. Understanding these applications helps illustrate the versatility of these connectors.

Energy Sector

In the energy sector, high voltage connectors are essential for connecting transformers, circuit breakers, and other critical equipment. These connectors ensure the safe and efficient transmission of electricity from generation facilities to substations and eventually to consumers. Their robust design allows them to withstand harsh environmental conditions, such as extreme temperatures and moisture.

Moreover, with the growing emphasis on renewable energy sources, high voltage connectors are increasingly used in solar and wind energy systems. They facilitate reliable connections between photovoltaic panels and inverters or between wind turbines and grid systems, ensuring optimal energy distribution.

Automotive Industry

The automotive industry is experiencing a significant transformation with the rise of electric vehicles (EVs). High voltage connectors are pivotal in EV applications, where they connect battery packs, motors, and charging stations. These connectors must withstand higher voltage levels and currents, making their design and material selection critical for vehicle performance and safety.

Additionally, high voltage connectors are used in hybrid vehicles and fuel cell systems, where reliability and efficiency are crucial for optimal operation. The ability to manage high power levels while ensuring user safety is a key advantage of these connectors.

Telecommunications

In telecommunications, high voltage connectors are utilized in various equipment, including base stations and power amplifiers. These connectors facilitate the transmission of electrical signals over long distances while minimizing signal loss and ensuring reliable performance. As the demand for faster and more efficient communication grows, the importance of high voltage connectors in this sector continues to expand.

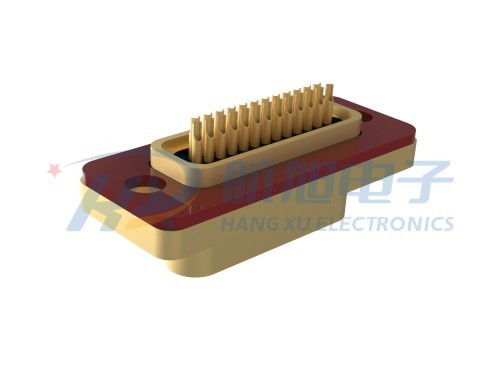

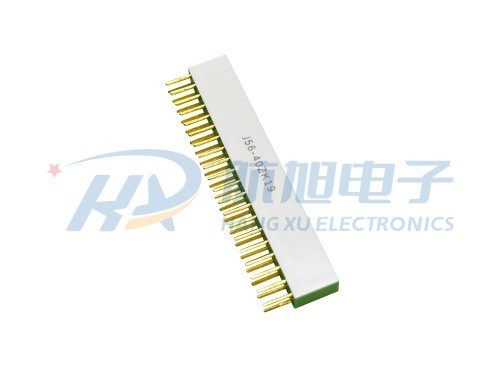

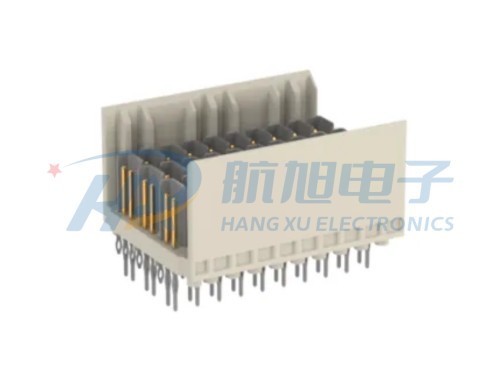

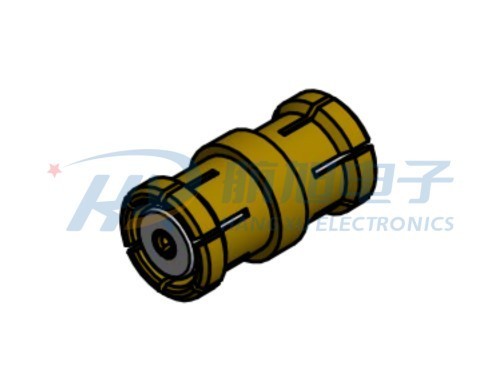

Types of High Voltage Connectors

High voltage connectors come in various types, each tailored to specific applications and requirements. Understanding these types can help in selecting the right connector for a given use case.

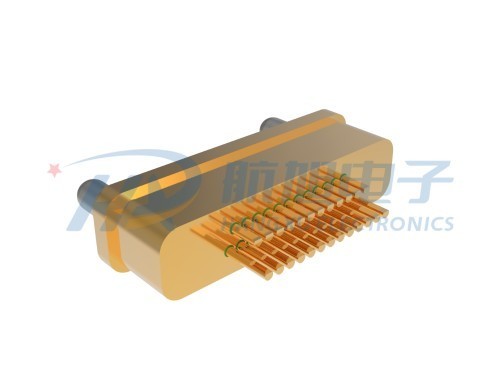

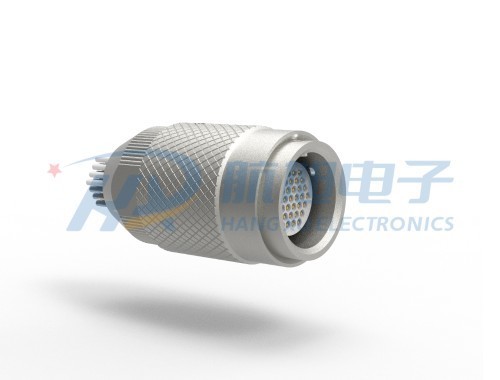

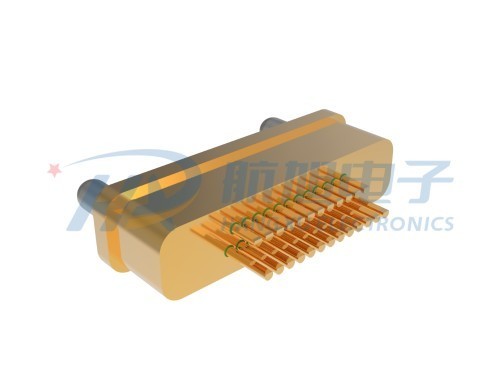

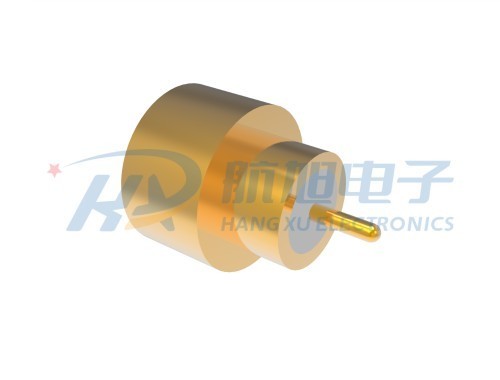

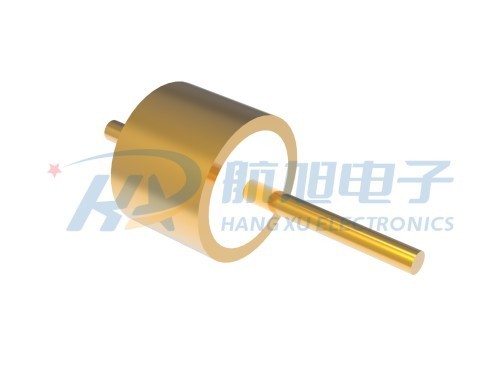

Molded Connectors

Molded connectors are designed with a one-piece construction that provides enhanced durability and protection against environmental factors. These connectors are ideal for applications where moisture, dust, or other contaminants are a concern. The molded design ensures a tight seal, preventing ingress and ensuring reliable performance even in harsh conditions.

Molded connectors are commonly used in outdoor applications, including renewable energy systems and heavy machinery, where reliability and toughness are paramount.

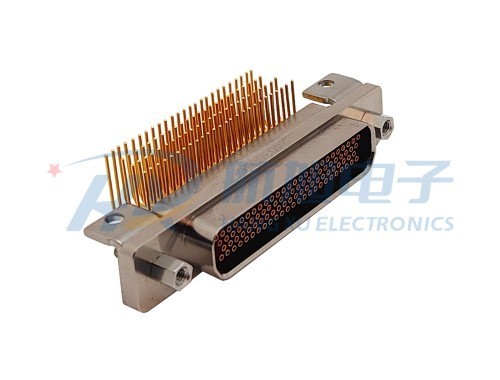

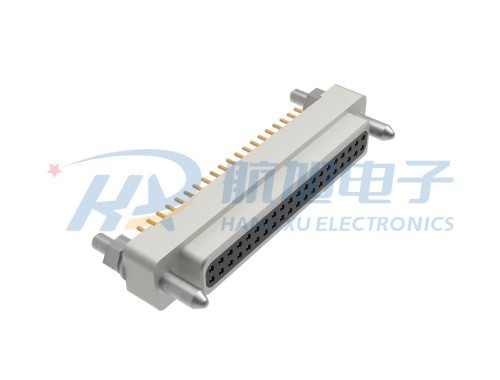

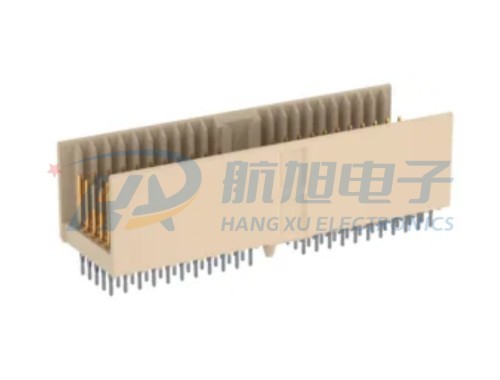

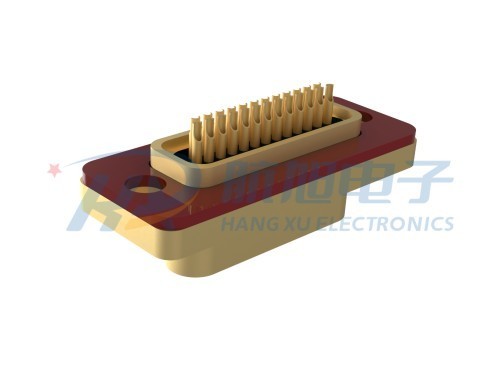

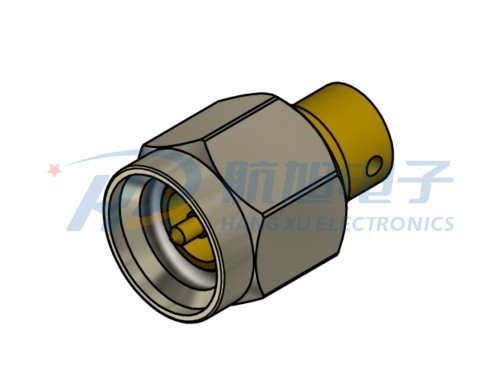

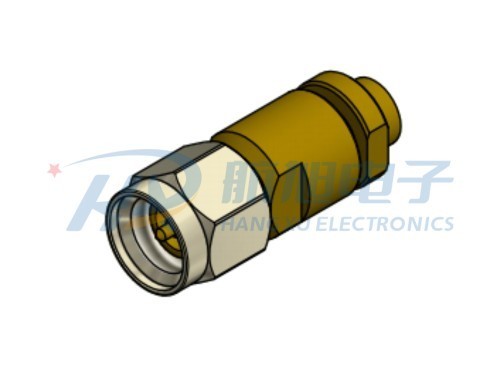

Panel Mount Connectors

Panel mount connectors are designed for secure mounting on panels and enclosures. These connectors facilitate easy access for maintenance and troubleshooting, making them a preferred choice in various industrial applications. They are available in different configurations, including circular and rectangular designs, allowing for flexibility in installation.

Panel mount connectors are widely employed in power distribution systems, control cabinets, and equipment interfaces, where a stable and secure connection is essential.

Advantages of Using High Voltage Connectors

The benefits of high voltage connectors extend beyond mere connectivity; they enhance system performance and longevity. Here are some of the notable advantages:

1. **Safety**: High voltage connectors are designed to mitigate risks associated with high electrical currents, reducing the chances of arcing and electrical failures.

2. **Reliability**: These connectors offer robust performance, ensuring stable connections even under fluctuating voltage levels and harsh environmental conditions.

3. **Durability**: Constructed from high-quality materials, high voltage connectors withstand mechanical stress and environmental challenges, leading to a longer service life.

4. **Efficiency**: By minimizing energy loss during transmission, high voltage connectors enhance overall system efficiency, contributing to lower operational costs.

5. **Versatility**: With various designs and configurations, high voltage connectors can be tailored to meet specific application requirements, making them suitable for a wide range of industries.

Challenges in High Voltage Connector Design

Despite their numerous advantages, designing high voltage connectors presents several challenges. Engineers must consider factors such as:

- **Material Selection**: Choosing the right materials for insulation and conductivity is crucial to prevent failures.

- **Thermal Management**: High voltage connectors generate heat, and effective thermal management is essential to maintain performance and safety.

- **Mechanical Stress**: Connectors must endure mechanical stress without compromising their integrity, necessitating rigorous testing and design optimization.

Addressing these challenges requires a deep understanding of electrical engineering principles and materials science, ensuring that connectors perform reliably in demanding applications.

Future of High Voltage Connectors

The future of high voltage connectors is promising, driven by advancements in technology and increasing demand for reliable electrical systems. Innovations such as smart connectors with integrated sensors are on the horizon, allowing for real-time monitoring of connector performance and health. As industries transition to more sustainable practices, the role of high voltage connectors in renewable energy systems will continue to grow, facilitating the integration of solar and wind power into mainstream energy grids.

Moreover, as electric vehicles become more prevalent, the demand for high voltage connectors in the automotive sector will rise, pushing manufacturers to innovate and improve existing designs.

Conclusion

High voltage connectors are essential components that ensure safety, reliability, and efficiency in various sectors, from energy to automotive and telecommunications. Their versatility and robust design make them indispensable in managing high electrical currents effectively. As technology evolves, high voltage connectors will continue to play a pivotal role in shaping the future of electrical systems.

FAQs

1. What are high voltage connectors used for?

High voltage connectors are used to establish reliable electrical connections in systems operating at voltages exceeding 1,000 volts, including energy generation and distribution, automotive applications, and telecommunications.

2. How do high voltage connectors enhance safety?

These connectors are designed to minimize risks associated with arcing and electrical failures, ensuring safe operation in high-voltage environments.

3. What types of high voltage connectors are available?

Common types include molded connectors for harsh environments and panel mount connectors for secure installation on equipment panels.

4. Why are materials important in high voltage connector design?

Material selection is critical for insulation and conductivity, impacting the connector's performance, durability, and safety.

5. What challenges do engineers face when designing high voltage connectors?

Engineers must address material selection, thermal management, and mechanical stress to ensure reliable performance in demanding applications.

In summary, high voltage connectors are integral to modern electrical systems, and understanding their versatility and applications can facilitate informed decisions in their use.

Related Documents

Related News