Unleashing the Power of RF Coaxial Cable Connectors: A Comprehensive Guide

2025-07-07

Unleashing the Power of RF Coaxial Cable Connectors: A Comprehensive Guide

Table of Contents

1. Understanding RF Coaxial Cable Connectors

2. Types of RF Coaxial Cable Connectors

2.1 BNC Connectors

2.2 SMA Connectors

2.3 N-Type Connectors

3. Applications of RF Coaxial Cable Connectors

3.1 Telecommunications

3.2 Broadcasting

3.3 Test Equipment

4. Installation Techniques for RF Coaxial Cable Connectors

4.1 Tools Required

4.2 Step-by-Step Installation Guide

5. Troubleshooting Common Issues with RF Coaxial Connectors

5.1 Signal Loss Problems

5.2 Physical Damage

5.3 Connection Issues

6. Best Practices for Using RF Coaxial Cable Connectors

7. Future Trends in RF Coaxial Cable Connectors

8. Frequently Asked Questions (FAQs)

9. Conclusion

1. Understanding RF Coaxial Cable Connectors

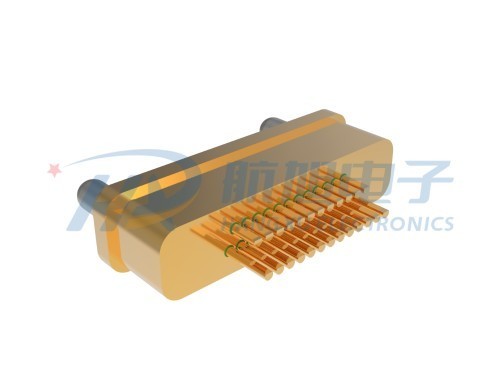

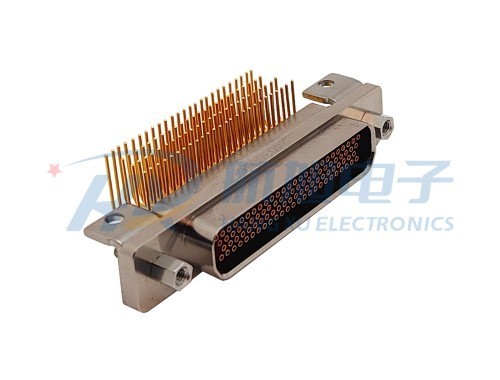

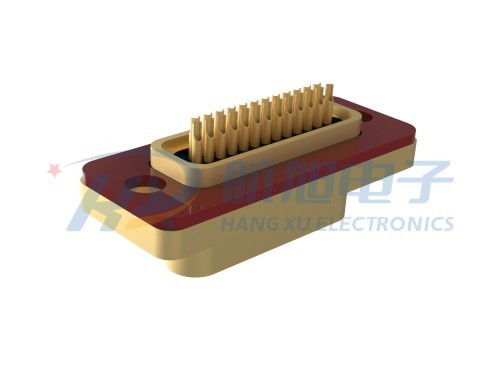

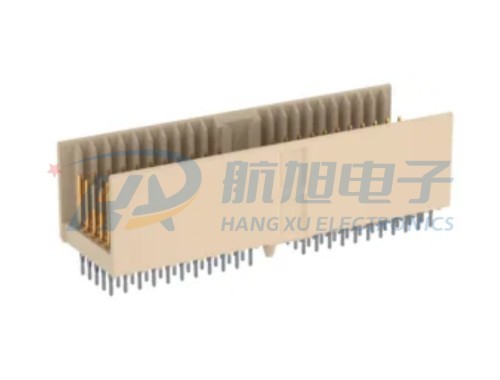

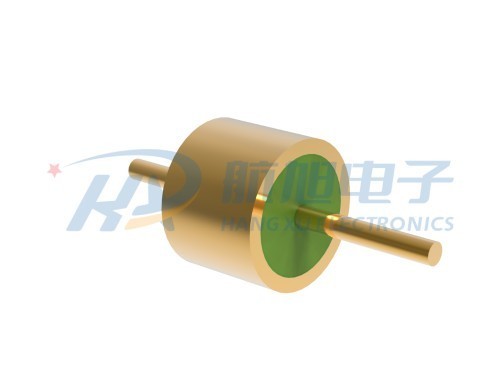

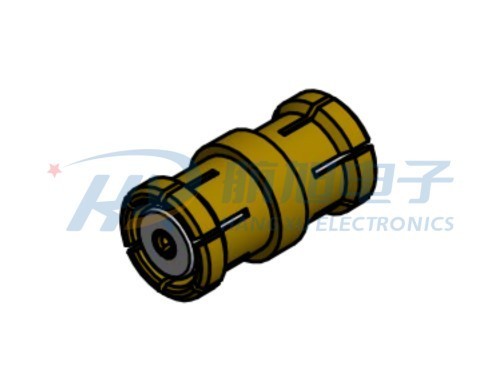

RF coaxial cable connectors play a crucial role in transmitting radio frequency signals. These connectors are designed to maintain the integrity of the signal while minimizing interference and loss. They consist of an inner conductor, insulation, and an outer shield, which collectively ensure a reliable connection in various applications, including telecommunications, broadcasting, and data transmission.

The importance of RF coaxial cable connectors stems from their ability to transmit high-frequency signals over long distances without significant degradation. As technology continues to evolve, the demand for these connectors has grown, making it essential to understand their functionalities and applications.

2. Types of RF Coaxial Cable Connectors

RF coaxial cable connectors come in various types, each designed to serve specific applications and performance requirements. Here, we delve into some of the most common types of RF connectors.

2.1 BNC Connectors

**BNC (Bayonet Neill-Concelman)** connectors are widely used for RF applications, particularly in video and data communication. Their bayonet coupling mechanism offers a secure connection, making them ideal for use in environments where quick connect and disconnect are essential. BNC connectors are common in television broadcasting, security cameras, and test equipment.

2.2 SMA Connectors

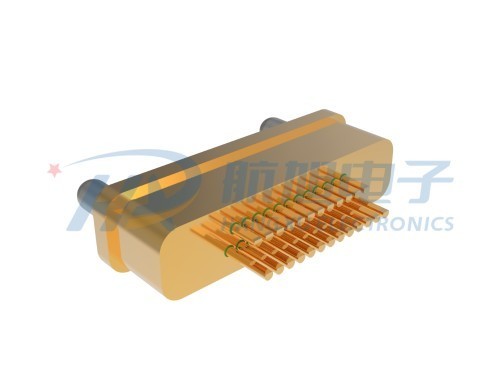

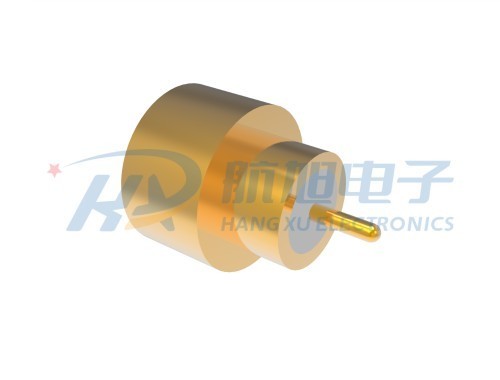

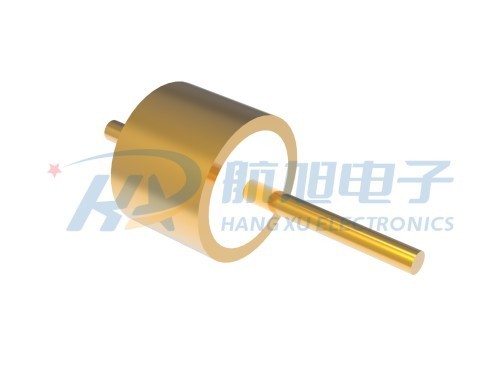

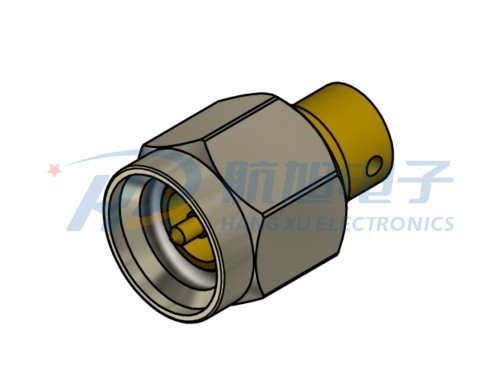

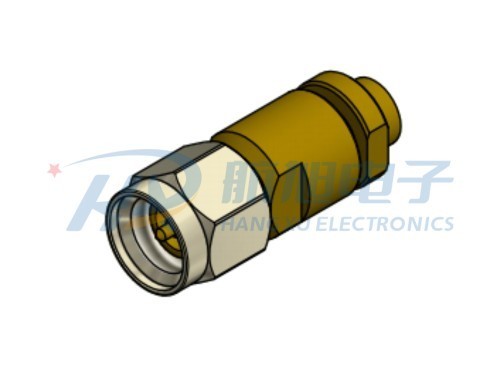

**SMA (SubMiniature version A)** connectors are known for their small size and high-performance capabilities. They are typically used in microwave applications and are compatible with a wide range of coaxial cables. The screw-type coupling mechanism provides excellent durability and reliability, making SMA connectors suitable for use in harsh environments.

2.3 N-Type Connectors

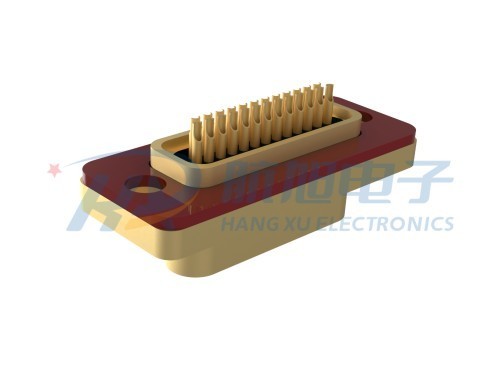

**N-Type** connectors are robust and designed for high-power applications. They feature a threaded coupling mechanism, ensuring a secure connection, even in outdoor environments. N-Type connectors are often used in radar systems, base stations, and antenna connections due to their ability to handle high frequencies and power levels.

3. Applications of RF Coaxial Cable Connectors

RF coaxial cable connectors find applications across various industries, each with unique requirements for signal integrity and performance.

3.1 Telecommunications

In telecommunications, RF coaxial cable connectors are crucial for transmitting signals between different network components. They are used in cellular networks, satellite communications, and cable television systems, ensuring high-quality signal transmission with minimal loss.

3.2 Broadcasting

The broadcasting industry relies heavily on RF coaxial cable connectors for transmitting audio and video signals. These connectors provide reliable connections between cameras, microphones, and broadcasting equipment, ensuring clear and uninterrupted signal transmission.

3.3 Test Equipment

In the realm of test equipment, RF coaxial connectors are used in various devices, including spectrum analyzers and signal generators. They facilitate precise measurements and testing, enabling engineers to evaluate the performance of RF systems accurately.

4. Installation Techniques for RF Coaxial Cable Connectors

Proper installation of RF coaxial cable connectors is vital to ensure optimal performance. This section outlines the tools and techniques required for successful installation.

4.1 Tools Required

To install RF coaxial cable connectors, you will need the following tools:

- Wire cutters

- Strippers

- Crimping tool

- Soldering iron (for solder-type connectors)

- Multimeter (for testing connections)

4.2 Step-by-Step Installation Guide

1. **Prepare the Cable**: Cut the coaxial cable to the desired length, ensuring you have enough slack for installation.

2. **Strip the Insulation**: Use the wire strippers to remove the outer insulation carefully. Expose the inner conductor and dielectric, ensuring no strands are damaged.

3. **Attach the Connector**: Depending on the type of connector (crimp or solder), attach it securely to the cable. For crimp connectors, insert the cable into the connector and use the crimping tool to secure it. For solder connectors, heat the soldering iron and apply solder to the connection point.

4. **Test the Connection**: Use a multimeter to test the connection for continuity and ensure there are no shorts or open circuits.

5. **Repeat**: Follow these steps for the other end of the cable or for additional connections as needed.

5. Troubleshooting Common Issues with RF Coaxial Connectors

Even with proper installation, issues may arise with RF coaxial cable connectors. This section addresses common problems and their solutions.

5.1 Signal Loss Problems

Signal loss can occur due to several factors, including poor connections, damaged cables, or incompatible connectors. To troubleshoot, check all connections and ensure they are secure and properly installed. Replace any damaged cables and verify that the connectors are compatible with the cable type.

5.2 Physical Damage

Physical damage to connectors can lead to performance issues. Inspect connectors for cracks, corrosion, or bent pins. If any damage is detected, replace the connector immediately to maintain optimal signal quality.

5.3 Connection Issues

Connection issues may manifest as intermittent signal loss or complete signal failure. Ensure that the connectors are properly seated and tightened. Sometimes, cleaning the contact points can resolve connection problems caused by dirt or oxidation.

6. Best Practices for Using RF Coaxial Cable Connectors

To maximize the performance and lifespan of RF coaxial cable connectors, adhere to the following best practices:

1. **Use High-Quality Connectors**: Invest in quality connectors designed for your specific application to minimize signal loss and ensure reliability.

2. **Avoid Sharp Bends**: When routing cables, avoid sharp bends or kinks, as these can damage the cable and connectors.

3. **Regular Maintenance**: Periodically inspect connectors and cables for signs of wear or damage, and replace them as necessary to maintain performance.

4. **Proper Storage**: Store unused connectors and cables in a dry, cool environment to prevent damage caused by moisture or extreme temperatures.

7. Future Trends in RF Coaxial Cable Connectors

As technology advances, RF coaxial cable connectors are evolving to meet new demands. Future trends include:

- **Miniaturization**: With the growing need for compact devices, manufacturers are developing smaller connectors that maintain performance without compromising signal quality.

- **Higher Frequency Applications**: As wireless communication continues to advance, there is a demand for connectors that can handle higher frequencies and improved bandwidth.

- **Sustainable Materials**: The industry is moving towards eco-friendly materials and manufacturing processes, reducing the environmental impact of RF connector production.

8. Frequently Asked Questions (FAQs)

**Q1: What is the difference between crimp and solder connectors?**

A1: Crimp connectors use a mechanical connection for attachment, while solder connectors involve melting solder to create a secure bond. Crimp connectors are generally quicker and easier to install, while solder connections offer excellent reliability.

**Q2: How do I choose the right RF coaxial connector for my application?**

A2: Consider the frequency range, power handling, and environmental conditions of your application. Consult manufacturer specifications to ensure compatibility with your existing components.

**Q3: Can I reuse RF connectors?**

A3: Reusing RF connectors is possible, but it is crucial to inspect them for damage and ensure they maintain a secure connection. If they show signs of wear, it is best to replace them.

**Q4: How do I clean RF coaxial connectors?**

A4: Use a soft, lint-free cloth to clean the contact points. For stubborn dirt or oxidation, use a mild cleaning solution and ensure the connectors are dry before reconnection.

**Q5: What factors contribute to signal loss in RF coaxial cables?**

A5: Signal loss can result from factors such as cable length, connector quality, environmental interference, and improper installation techniques.

9. Conclusion

RF coaxial cable connectors are integral to modern technology, enabling reliable transmission of high-frequency signals across various applications. By understanding their types, installation techniques, and troubleshooting methods, we can fully harness the potential of these connectors. As technology continues to evolve, staying informed about best practices and future trends will ensure optimal performance and longevity in RF applications. Whether you're working in telecommunications, broadcasting, or test equipment, mastering RF coaxial cable connectors will significantly improve your projects' reliability and efficiency.

Related Documents

Related News