How to Choose the Right PCB Mount Connector for Your Application

2025-07-21

How to Choose the Right PCB Mount Connector for Your Application

When it comes to designing electronic circuits, the choice of connectors plays a crucial role in ensuring reliability, performance, and ease of assembly. Whether you are working on consumer electronics, industrial equipment, or automotive systems, selecting the right PCB mount connector is essential. In this article, we’ll explore the various types of PCB mount connectors, their features, and the key factors to consider when making your selection, to help you make the best decision for your application.

Table of Contents

- Understanding PCB Mount Connectors

- Types of PCB Mount Connectors

- Key Specifications to Consider

- Environmental Considerations

- Installation and Assembly

- Making an Informed Decision

- Frequently Asked Questions

- Conclusion

Understanding PCB Mount Connectors

PCB mount connectors are components that facilitate the connection between different electronic devices and circuit boards. They can be found in a myriad of applications, ranging from simple consumer electronics to complex industrial control systems. Understanding the fundamental role of these connectors is essential for making an informed choice.

These connectors are typically soldered onto printed circuit boards (PCBs), providing a reliable physical and electrical connection. The design of PCB connectors can vary significantly, with different shapes, sizes, and configurations to meet various needs.

Types of PCB Mount Connectors

Choosing the right type of PCB mount connector is pivotal. There are several categories of connectors, each suited for specific applications. Here are some common types:

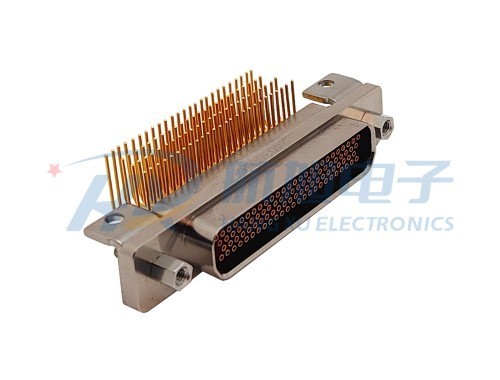

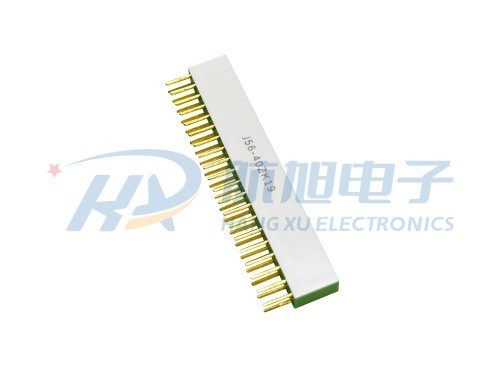

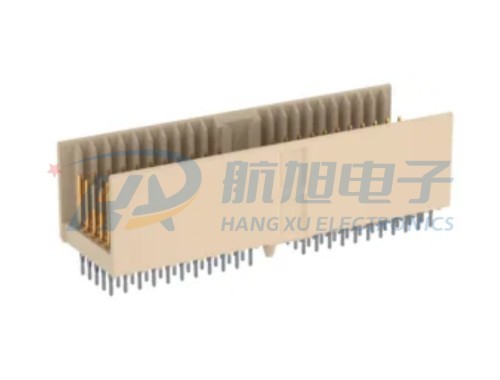

1. Pin Header Connectors

Pin headers are among the most widely used PCB connectors. They consist of a row of pins that are soldered onto the PCB, allowing for easy insertion of mating connectors. Pin headers are commonly used in prototyping and are ideal for applications requiring frequent disconnection and reconnection.

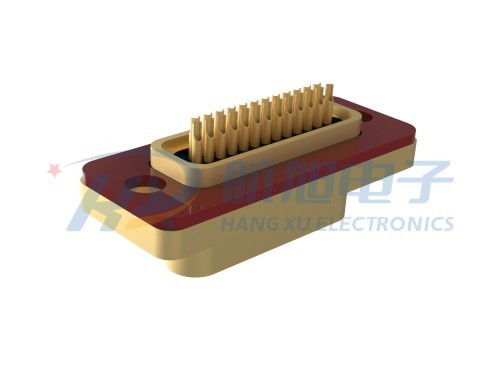

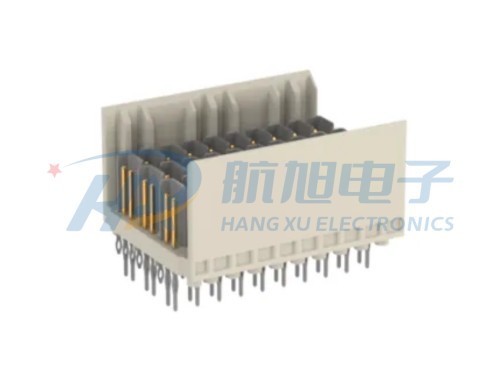

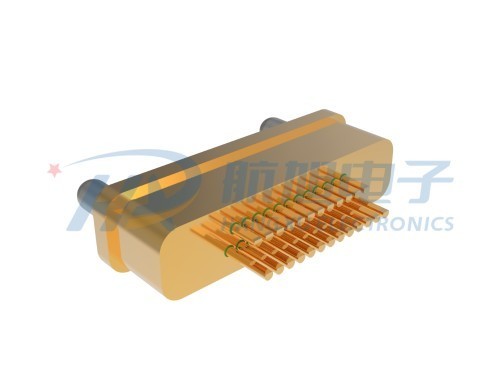

2. Socket Connectors

Socket connectors are designed to accept pin headers or similar components. They provide a secure and reliable connection and are often used in applications where space is limited. Sockets are beneficial for modular designs, allowing for easy replacement of components.

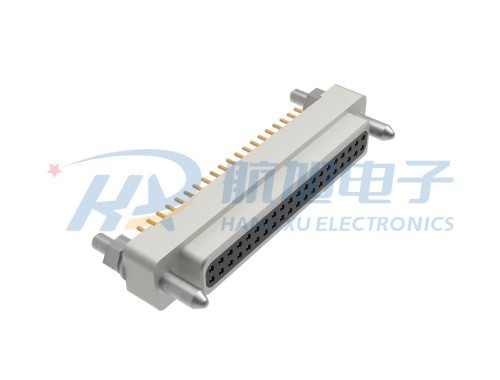

3. IDC Connectors

Insulation Displacement Connectors (IDC) are used to connect flat ribbon cables to PCBs. They are designed to pierce the insulation of the cable, creating a reliable connection without the need for stripping the wire. IDC connectors are widely used in telecommunications and data communication applications.

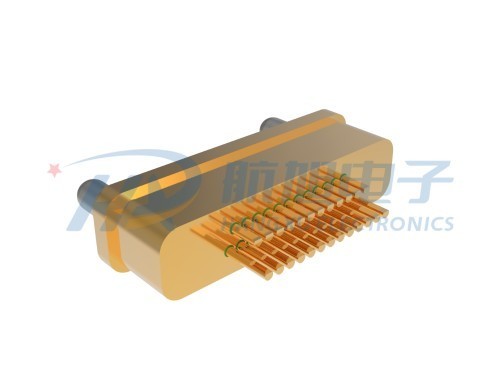

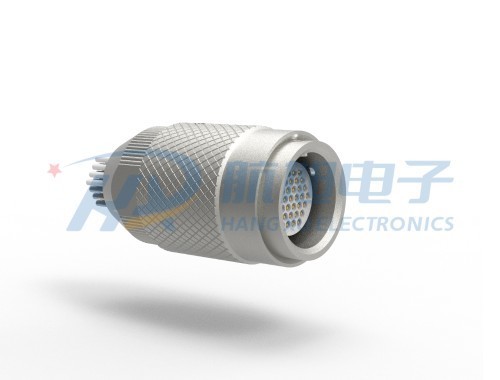

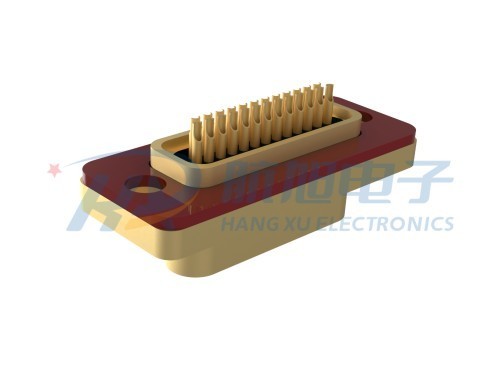

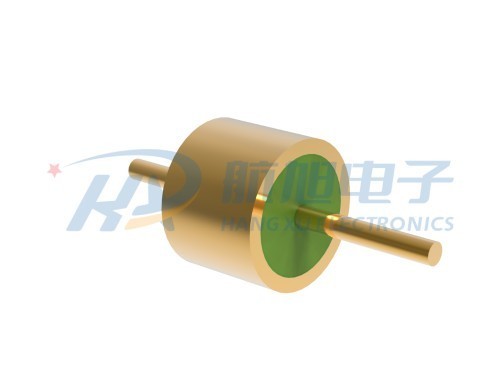

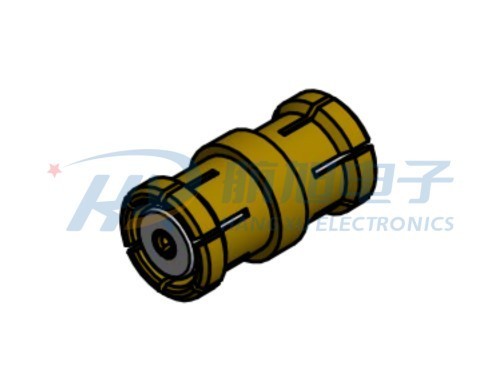

4. Circular Connectors

Circular connectors are robust and offer a high degree of reliability in harsh environments. They are designed for applications requiring durability and are often used in automotive, military, and aerospace industries.

5. USB Connectors

USB connectors are essential for data transfer and power supply in many electronic devices. Their standardization makes them versatile and user-friendly. Choosing the right USB connector type (USB-A, USB-B, USB-C) is critical based on the application requirements.

Key Specifications to Consider

When selecting PCB mount connectors, several specifications should be evaluated to ensure the connector meets your application's requirements:

1. Current Rating

The current rating indicates the maximum amount of electrical current the connector can safely handle. It is crucial to select a connector with a current rating that exceeds the maximum current your application will draw.

2. Voltage Rating

Voltage ratings determine the maximum voltage that can be applied across the connector without risk of breakdown. Ensure that the voltage rating of the connector matches or exceeds the voltage levels in your application.

3. Contact Resistance

Low contact resistance is essential for maintaining signal integrity. High resistance can lead to power loss and generate heat, potentially damaging the connector and connected components.

4. Operating Temperature Range

Different environments require different temperature ratings. Ensure the connector can operate efficiently within the temperature range expected in your application to prevent performance issues or failures.

5. Mechanical Durability

Mechanical durability is a measure of how many times a connector can be mated and unmated without failure. This is especially important in applications where frequent connections are made.

Environmental Considerations

In many cases, the environment in which the connector will operate can significantly impact its performance and longevity:

1. Moisture and Humidity

Connectors used in humid environments should have appropriate sealing and coatings to prevent corrosion and ensure reliable connections. Look for connectors rated for moisture resistance if applicable.

2. Chemical Exposure

For applications in chemical environments, select connectors that are resistant to the chemicals they will encounter. Materials like thermoplastic or metal housings can provide better chemical resistance.

3. Vibration and Shock Resistance

In applications subject to vibration and shock, connectors must be robust enough to withstand these forces without losing connection integrity. Look for connectors with locking mechanisms or those designed to absorb vibration.

Installation and Assembly

The installation process of PCB mount connectors can vary based on the type of connector and PCB design:

1. Soldering Techniques

Understanding proper soldering techniques is vital to ensure strong connections and reliability. Consider using automated soldering methods for high-volume production to enhance consistency and reduce labor costs.

2. Connector Orientation

Ensure correct orientation of the connectors during assembly to prevent damage and ensure proper functionality. This is particularly important for polarized connectors.

3. Testing and Quality Assurance

Post-installation testing is crucial to ensure that the connectors function as intended. This could include continuity tests, stress tests, and thermal analysis to confirm reliability.

Making an Informed Decision

After considering the various types of connectors, specifications, and environmental factors, it’s time to make an informed decision. Start by assessing your application’s specific requirements, including electrical, mechanical, and environmental conditions. Then, weigh the options based on reliability, cost, and availability.

It may also be beneficial to consult with manufacturers or suppliers who can provide insights and recommendations based on their experience and product offerings. This collaborative approach can lead to the selection of the most suitable PCB mount connector for your needs.

Frequently Asked Questions

1. What is the difference between pin headers and socket connectors?

Pin headers are male connectors with exposed pins, while socket connectors are female connectors designed to accept pin headers. Pin headers are ideal for prototyping, while sockets are better for modular designs.

2. How do I determine the current rating for my application?

To determine the current rating, assess the maximum current that will flow through the connector in your specific application. It’s advisable to choose a connector rated for at least 20-30% more than the maximum expected current.

3. Are there connectors specifically designed for high-temperature applications?

Yes, there are connectors designed to withstand high temperatures. Look for connectors made from heat-resistant materials and check their specified operating temperature range to ensure compatibility with your application.

4. What are the advantages of using IDC connectors?

IDC connectors offer ease of use in connecting flat ribbon cables without the need for wire stripping, making assembly faster and reducing the risk of human error during installation.

5. How can I ensure the reliability of my connectors in harsh environments?

Select connectors specifically rated for harsh conditions, including moisture, chemical exposure, and vibration. Additionally, ensure proper sealing and installation techniques to enhance reliability.

Conclusion

Selecting the right PCB mount connector for your application is a critical process that requires careful consideration of various factors. From understanding the types of connectors available to evaluating specifications and environmental conditions, this guide has provided a comprehensive overview to aid your decision-making. By focusing on the specific needs of your application and leveraging the insights provided, you can ensure the reliability and functionality of your electronic designs. Always stay informed about advancements in connector technology and innovations to make the best choices for your projects and applications.

Related Documents

Related News